MaterialNEXT 5.0 (2024)

MaterialNEXT 5.0 has 2 parallel tracks for participation:

- Research Track

- Start-up Track

MaterialNEXT 5.0 also has 4 Technology Theme Areas open to both tracks.

Advanced materials play a fundamental role in developing breakthrough technologies for a sustainable future. To further explore use of advanced materials in identified emerging technology theme areas, sub-areas have been identified in each area from current and future industry relevance.

Ideas and proposals are invited in these sub-areas through research or start-up track after registration. Please refer the eligibility and rules below, before registering in applicable track.

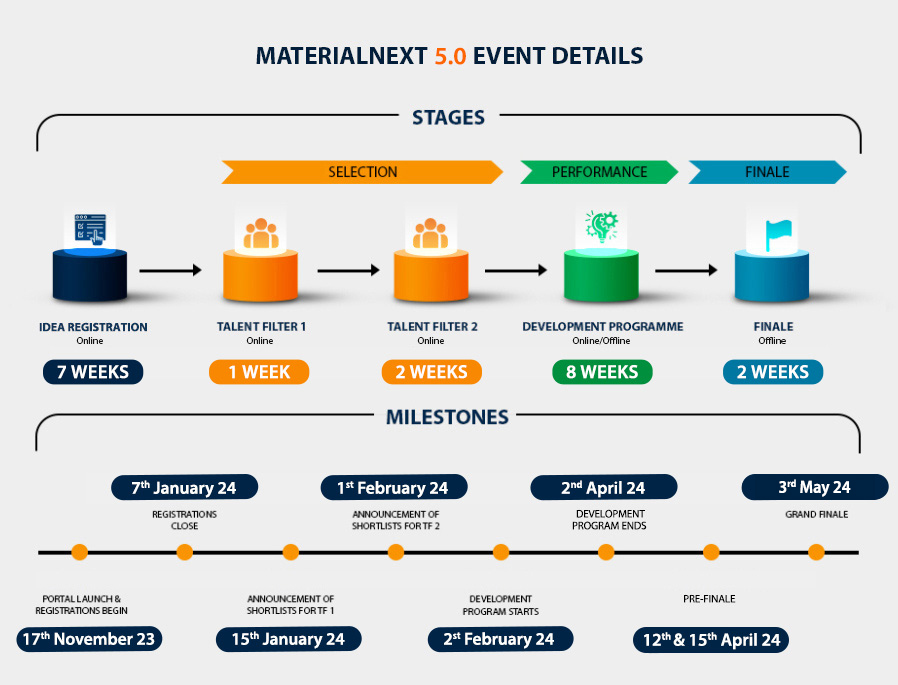

The event would consist of 3 Major Phases: Selection, Performance and Finale. After registration by teams, the Selection Phase is a 2-stage process of an online screening followed by discussion-cum-evaluation stage, conducted by subject matter experts. The selected entries will progress to Performance Phase. Performance Phase ends with an evaluation (Pre-Finale) round.

The Selected entries from this phase qualify for the Finale Phase and will be called for the Grand Finale to decide winner and runner-up. Please refer the depiction below on event details and timelines.

Winner and runner-up teams from both the track gets awarded with cash prizes. Also, post-event mentorship and grants for next level of development will be provided, if applicable.

Click here to Register

MaterialNEXT 4.0 (2023)

With encouraging responses during first, second & third editions, fourth edition was launched on November 26th, 2022. The fourth edition of the initiative was launched across pan-India as a flagship event of Tata Steel on four key themes/challenges: Applied Nanomaterials, Energy Materials, Novel Composites & Emerging Construction Materials.

MaterialNEXT 4.0 had two tracks: first one for aspiring registered PG and Ph.D. students & research scholars from academia/research centres and second one for the incubated start-ups in seed or series A funding level. Teams competed for the cash prizes, mentorship, and grants for next level of idea developments.

The program received registrations from 180 teams with final 158 active ideas (140 in Research track and 18 in Startup track). After the two-stage selection process, 22 top ideas were onboarded for a guided idea development for 2 months. During the idea development/performance phase, all teams received interactive mentoring sessions from the industry specialists cum challenge area owners from Tata Steel and subject matter experts from reputed technical/research institutes. The teams were also supported with small revenue expenditure funds as per activity estimates. All top projects were evaluated and among them 8 pre-finalist teams were selected to participate in grand finale.

The grand finale event was held physically at SNTI, Jamshedpur on 11th May 2023. The finale jury comprised of Dr. Bhagavatula L.V. Prasad, Director, Centre for Nano & Soft Matter Sciences (CENS), Bangaluru; Dr Ramanuj Narayan, Senior Principal Scientist & Chair-IICT Hyderabad; Dr Abhaykumar M Kuthe, Professor (HAG), VNIT, Nagpur; Mr. Peeyush Gupta – Vice President, Group Strategic Procurement & Supply Chain, Tata Steel, Mr. Vinay Mahasabde, Chief R&D and Product Technology, Tata Steel.

Team “Breath Applied Science Pvt. Ltd.” of Jawaharlal Nehru Centre for Advanced Scientific Research (JNCASR) emerged as the winner of MaterialNEXT 4.0 for developing a solution on “Integrated technologies for sustainable & economical production of Methanol from CO2”. Team “High Energy Zone” of TIFR, Hyderabad was declared as the 1st runner-up for “Development of high-performance rechargeable Zinc-air batteries”.

Two 2nd Runner up teams were identified as the intense competitive outcome of the event. Team “Interface Icon” of NIT, Rourkela demonstrated solution for “Hybrid Composite for Hydrogen Storage Tanks” followed by Team “Graphecon Materials” of IIT Guwahati for presenting solution on “Sustainable durable geopolymer coating through homogeneous dispersion of Graphene”.

MaterialNEXT 3.0 (2022)

With encouraging responses during first edition & second edition, third edition was launched on December 16th, 2021. The third edition of the initiative was launched across pan-India as a flagship event of Tata Steel on four key themes/challenges: Material Recycle & Recovery, Hydrogen & CO2, Alternate Construction Materials & Nano Materials

MaterialNEXT 3.0 had two tracks: first one for aspiring registered PG and Ph.D. students & research scholars from academia/research centres and second one for the incubated start-ups in seed or series A funding level. Teams competed for the cash prizes, mentorship, and grants for next level of idea developments.

The program received registrations from 278 teams with final 166 active ideas (151 in Research track and 15 in Startup track). After the two-stage selection process, 25 top ideas were onboarded for a guided idea development for 2 months. During the idea development/performance phase, all teams received interactive mentoring sessions from the industry specialists cum challenge area owners from Tata Steel and subject matter experts from IITs, NITs and IISc. The teams were also supported with small revenue expenditure funds as per activity estimates. All top projects were evaluated and among them 8 pre-finalist teams were selected to participate in grand finale.

The grand finale event was held physically at Beldih Club, Jamshedpur on 1st June 2022. The finale jury comprised of Mr. Indranil Chattoraj, Director, CSIR-NML, Jamshedpur; Mr. Ashish Anupam, Managing Director, Tata Steel Long Products; Dr. Debashish Bhattacharjee, Vice President, Technology & New Material Business, Tata Steel; Mr. Peeyush Gupta – Vice President, Supply Chain Tata Steel.

Team “Nano Tribe” from IIT, Hyderabad won the MaterialNEXT 3.0 for developing a prototype of “Self-powering sensor to detect pre-diabetes in human breadth”. Team “Materials Engineering Lab” from IACS, Kolkata was declared as the 1st runner-up for developing “Facile, high yield & room temperature synthesis process for 2D materials. Team “TCN-IITRPR” of IIT Ropar bagged 2nd runner-up position for showcasing the solution titled “Recovery of pure hydrogen from H2S by greener electrochemical approach”.

MaterialNEXT 2.0 (2021)

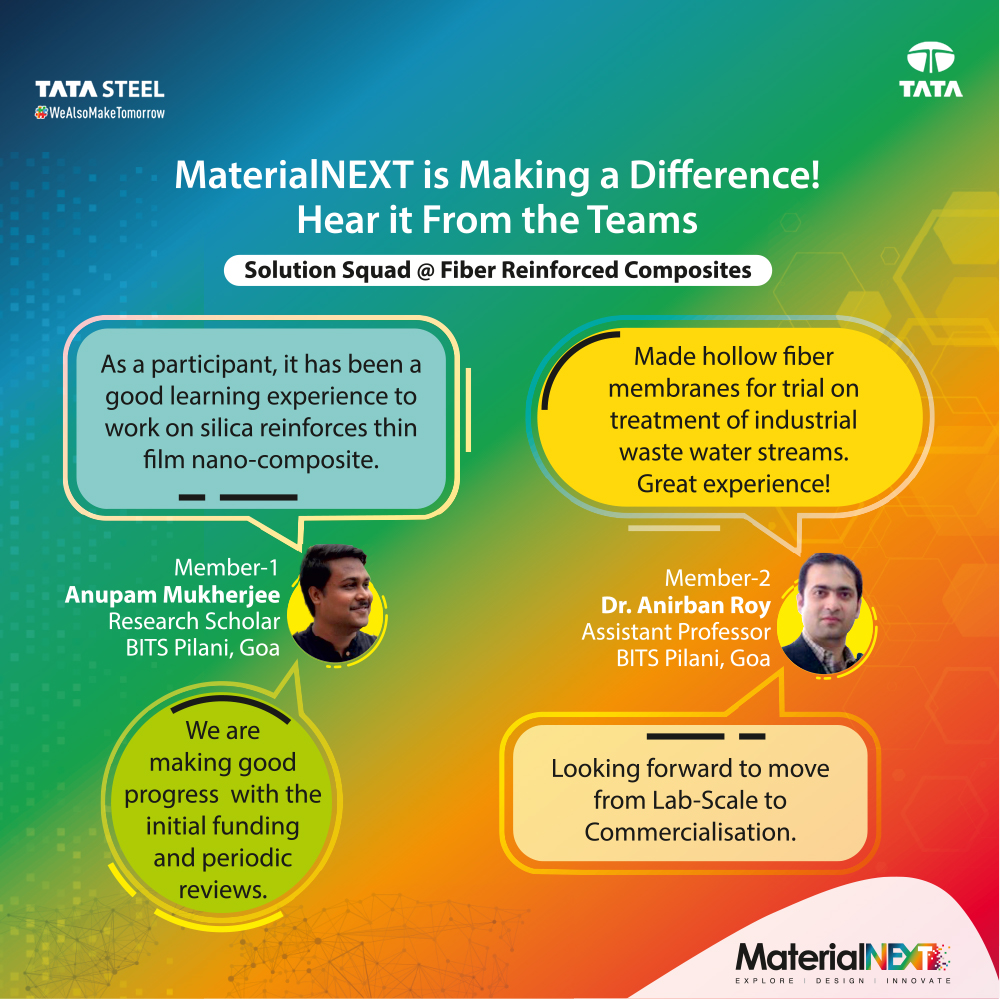

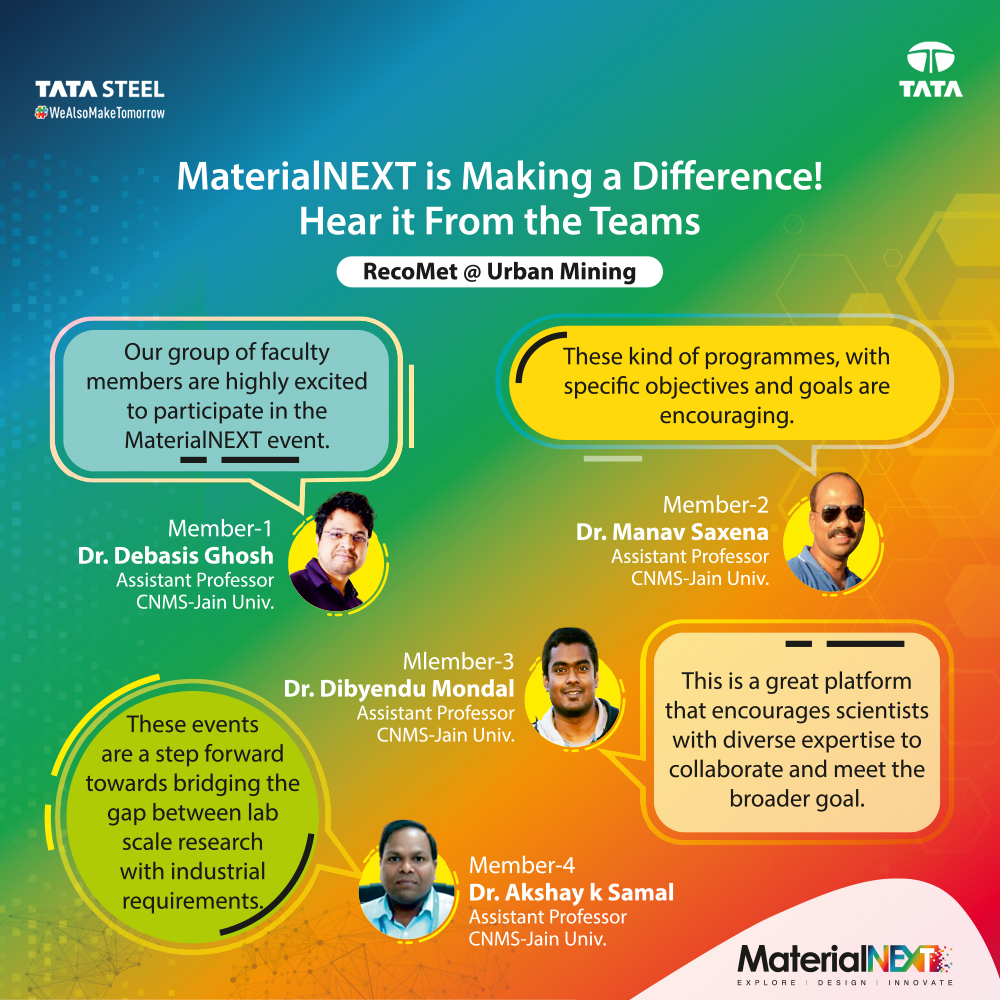

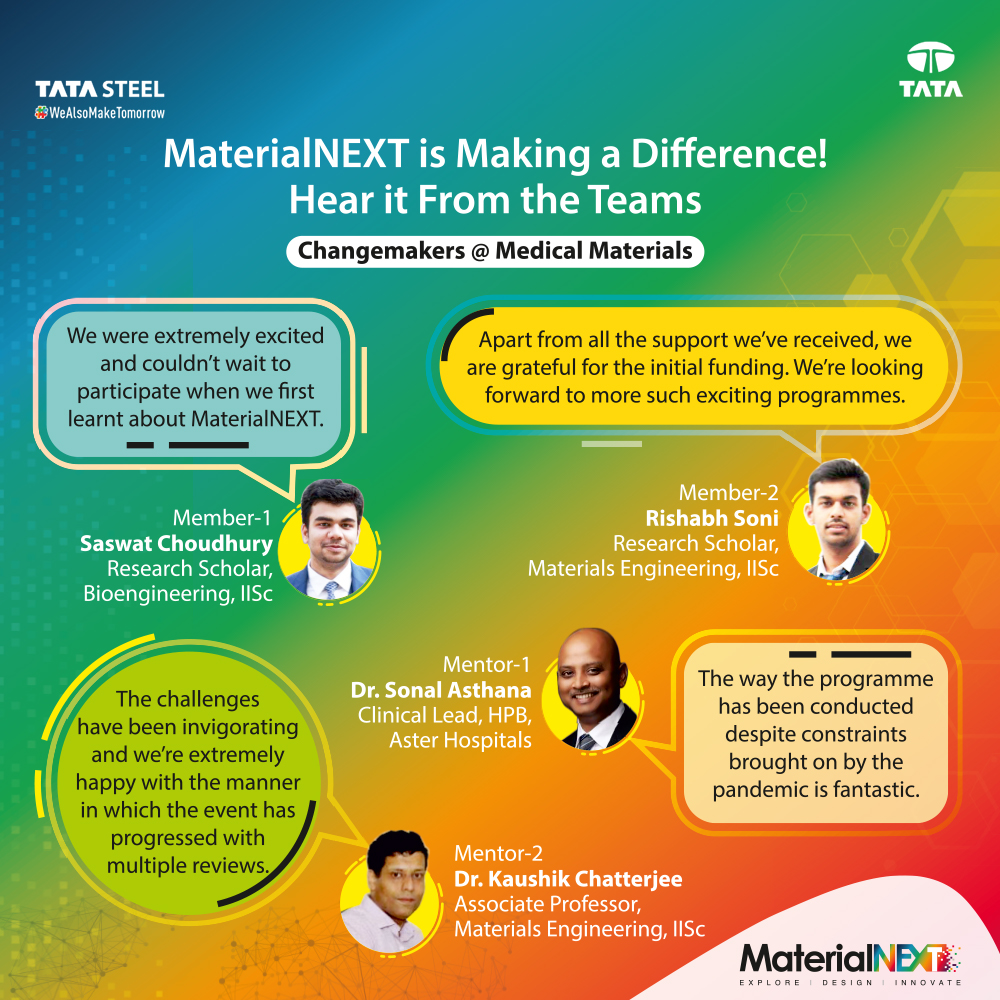

With encouraging responses during first edition, second edition was launched on December 28, 2020, coinciding with the birthday of Mr. Ratan N Tata, Chairman Tata Trusts and Chairman Emeritus Tata Sons. The second edition of the initiative was launched across pan-India as a flagship event of Tata Steel on four key themes/challenges: Fiber Reinforced Composites, Novel Coatings, Urban Mining and Medical Materials.

MaterialNEXT 2.0 had two tracks: first one for aspiring registered PG and Ph.D. students & research scholars from academia/research centres and second one for the incubated start-ups in seed or series A funding level. Teams competed for the cash prizes, mentorship, and grants for next level of idea developments.

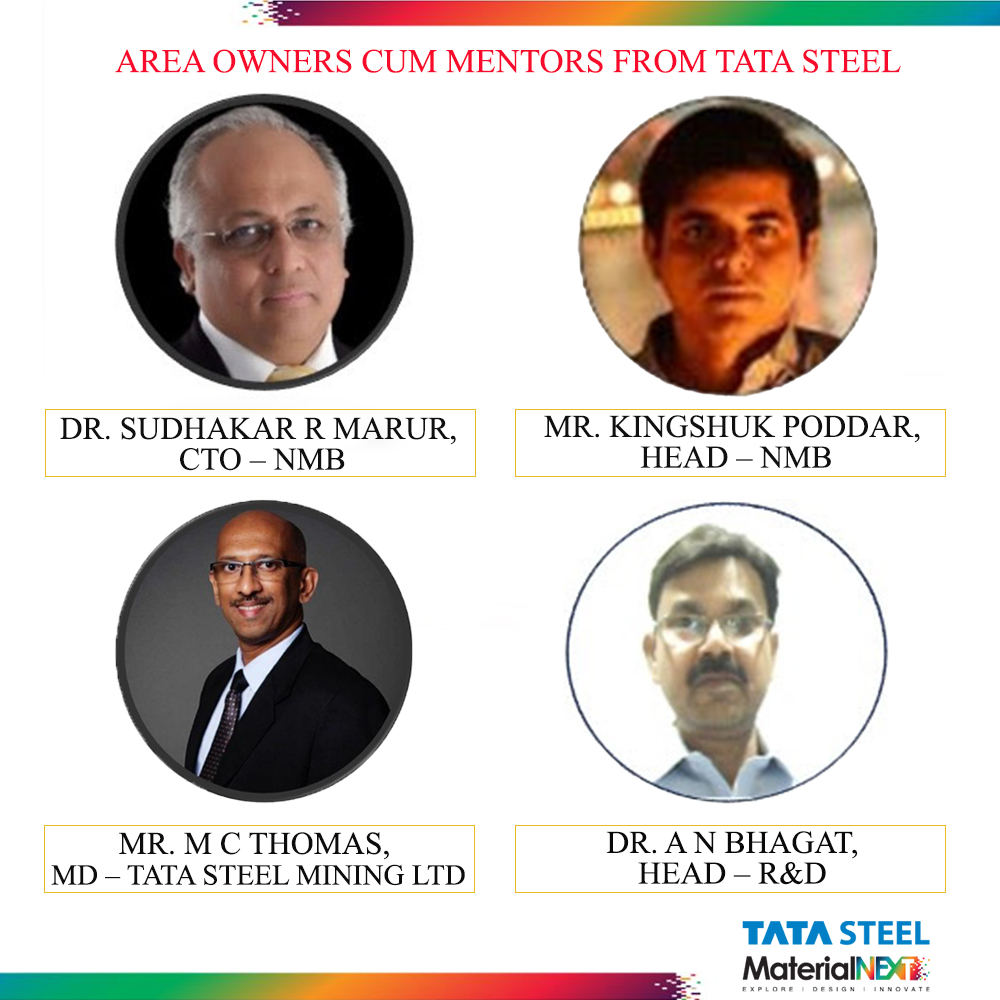

The program received registrations from 250 teams with final 91 active ideas (68 in Research track and 23 in Startup track). After the two-stage selection process, 15 top ideas (13 in Research track and 2 in Startup track) were onboarded for a guided idea development for 2-3 months. During the idea development/performance phase, all teams received interactive mentoring sessions from the industry specialists cum challenge area owners from Tata Steel and subject matter experts from IITs, NITs and IISc. The teams were also supported with small revenue expenditure funds as per activity estimates.

The grand finale was held as an online event on July 9, 2021. The grand finale jury comprised Dr. Tata Narasinga Rao, Director, ARCI Hyderabad; Dr. Debashish Bhattacharjee, Vice President, Technology & New Material Business, Tata Steel; Mr. Ravi Arora, Vice President, Innovation Program, Tata Sons.

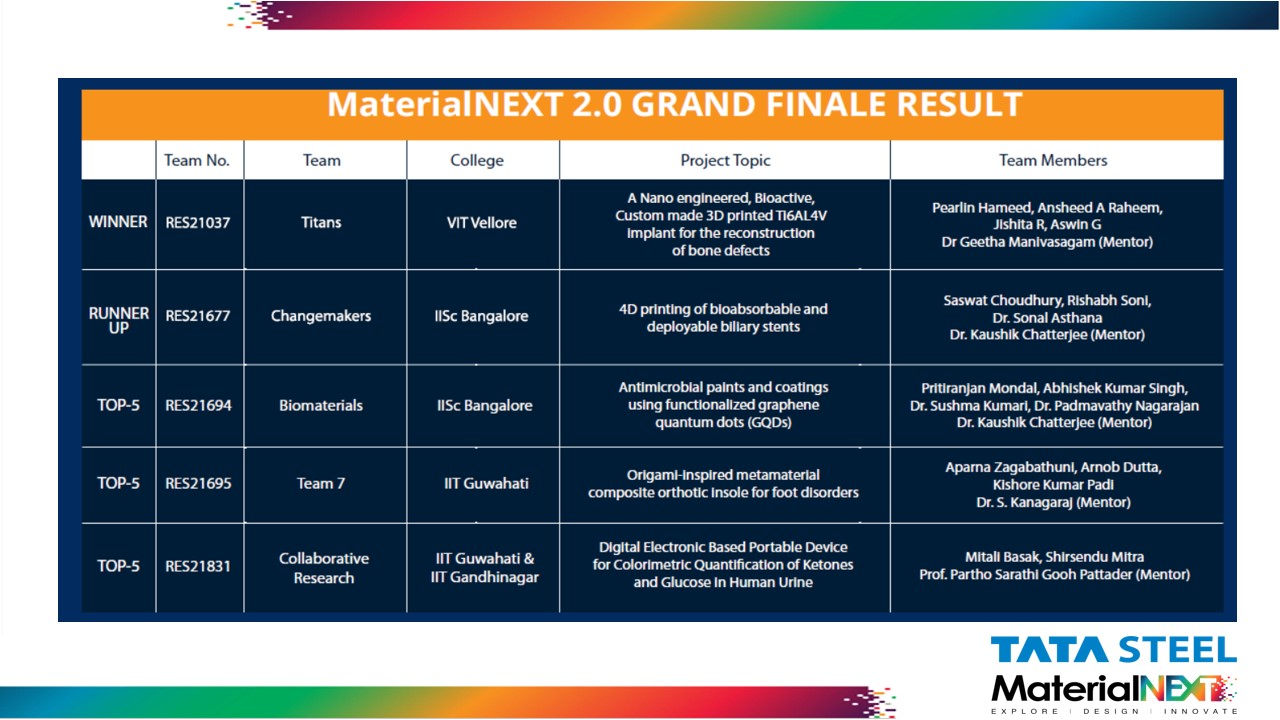

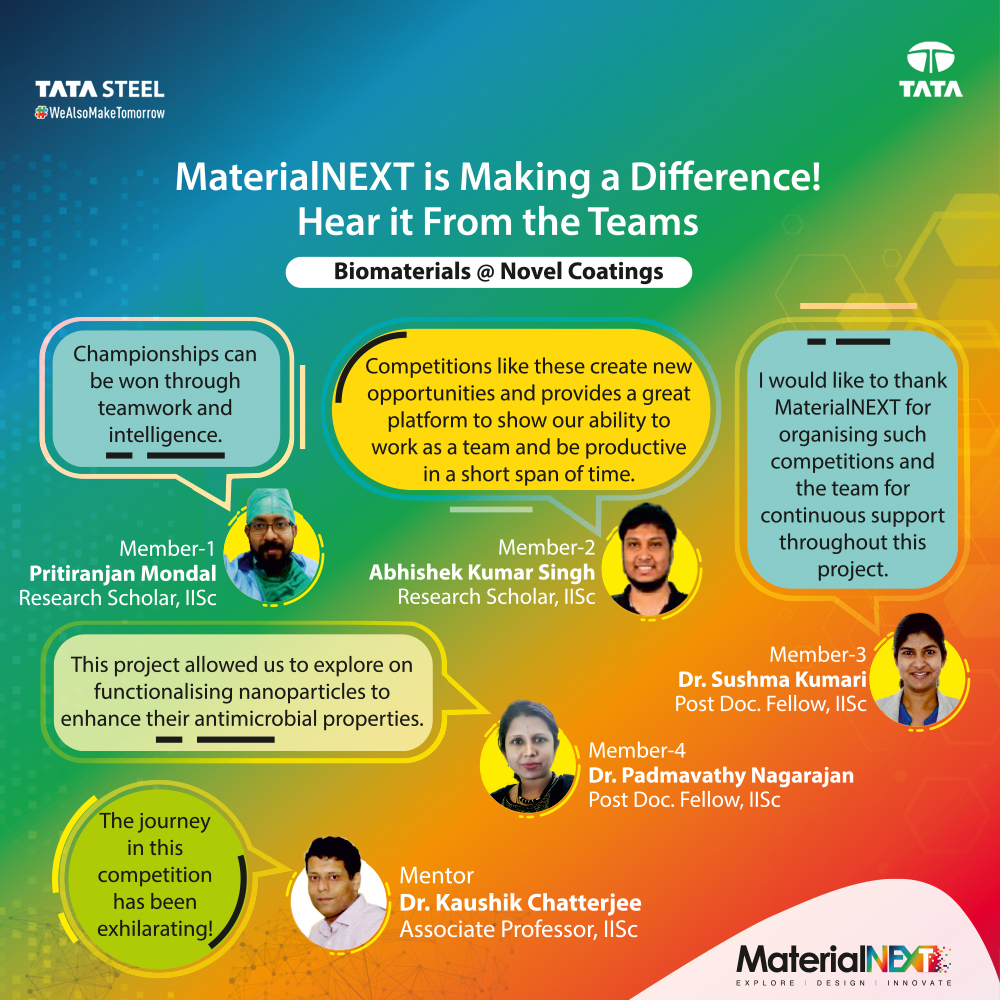

Team Titans from VIT, Vellore won the MaterialNEXT 2.0 for developing a prototype of a Titanium alloy implant for the reconstruction of bone defects. Team Changemakers from IISc, Bangalore was declared as the runner-up for creating prototypes of biodegradable & deployable gastrointestinal stents using shape memory polymer composites. The remaining three teams in the top 5 was, Team Biomaterials from IISc Bangalore, Team 7 from IIT Guwahati, Team Collaborative Research from IIT Guwahati and IIT Gandhinagar.

For more detail please visit the press release

MaterialNEXT 1.0 (2019)

The 1st edition of MaterialNEXT was conducted in 2019 in collaboration with the Entrepreneurship Cell, IIT Madras. The event offered a chance to the budding researchers, technology developers and enthusiasts in the field of advanced materials, to propose, produce and present their solution model to experts for the 4 different industrial challenges posed.

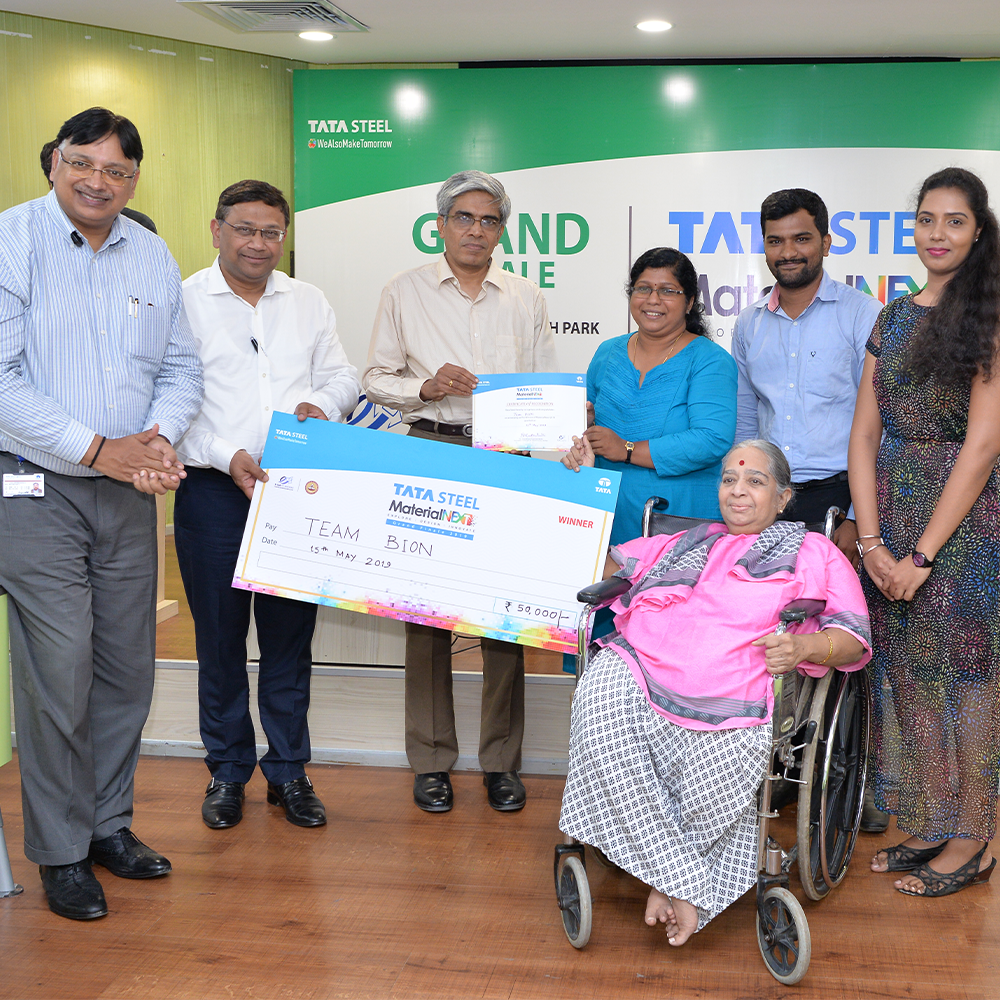

The first edition, involving three phases, received a registration of a total of 32 teams and 11 teams were selected. In the second phase, teams were given eight weeks to work on their preliminary proposals. The top five teams, selected at the end of second phase, moved to the third and final phase of grand finale. The grand finale was held on May 15, 2019 in Chennai.

Team BION from IIT Madras, which created an innovative solution and prototype using Graphene Oxide (GO)-based flexible sweat sensors, won the first edition of the MaterialNEXT.

Team BION, comprising Dr. V.T. Fidal Kumar, Dr. Chithra Lekha P, Dr. S Balamurugan and Ms. Desika Prabhakar, was mentored by Prof. T S Chandra from IIT Madras and Dr. Chandrani Pramanik from Tata Steel

For more detail please visit the press release

Corporate

Corporate

Sustainability

Sustainability

Products & Solutions

Products & Solutions

Investors

Investors

Careers

Careers

Contact Us

Contact Us

Eligibility

Eligibility Rules

Rules Rewards

Rewards Contact Us

Contact Us