A greener tomorrow: Tata Steel paves way for building a state-of-the-art environment-friendly Coke Plant at its Jamshedpur Works; completes controlled demolition of obsolete facilities

~ Successfully executes scheduled controlled implosion of two facilities today - Battery#6 Chimney and a Coal Tower ~

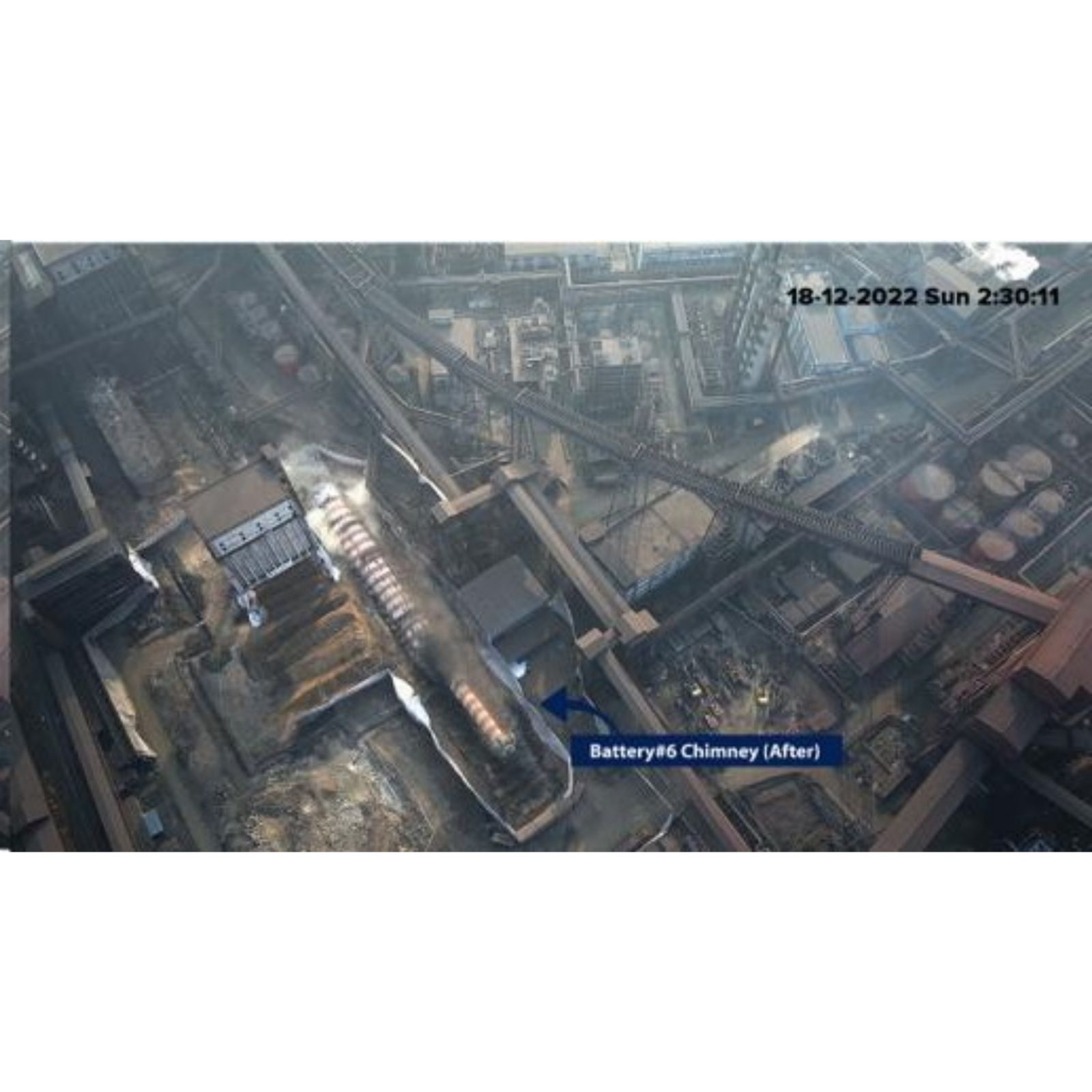

Tata Steel today successfully executed the implosion of two obsolete Coke Plant facilities - Battery#6 Chimney and a Coal Tower - at its Jamshedpur Works under controlled conditions, reinforcing the Company's engineering prowess.

Taking giant strides towards a better tomorrow, Tata Steel is replacing the existing Coke Oven Batteries 5, 6 and 7 (combined capacity of 1MnTPA) with new Coke Oven Batteries 6A and 6B (combined capacity of 1MnTPA) in Jamshedpur, with the latest technology and higher energy efficiency.

Today's implosions mark the completion of the dismantling process of obsolete high-rise facilities at the Coke Plant in Jamshedpur Works, which has many firsts to its credit. In a first-of-its-kind engineering process in the world, Tata Steel carried out these implosion activities in an operating steel plant, involving mega structures, tallest in India.

The first implosion of a Model Repair Shop of 12-meter height was executed on September 4, 2022, to establish the safe operating procedure inside an operational plant and on November 27, 2022, the Company successfully executed the implosion of an obsolete 110-metre-tall chimney (Battery #5 Chimney) at the Coke Plant. Today, another concrete Chimney of 110-meter height (Battery#6 Chimney) along with a 48-meter-tall Coal Tower were dismantled as planned in a safe and environment-friendly way. The implosions were carried out with the help of the contract partner, Edifice Engineering India, and supported by Jet Demolition South Africa.

The controlled implosion of the 110-metre-tall chimneys were executed using a mechanical hinge, enabling the structure to fall in one direction with zero degrees of deviation. ‘Water curtains’ were used to control dust and ‘trenches with berms’ were deployed to absorb vibration. Also, the use of ‘Steel wires mesh’ prevented the debris from getting scattered. The concrete debris generated out of these implosions will be recycled and used in Plain Cement Concrete (PCC), wall and road construction. Drones were deployed to improve visibility and help identify the hazards by reaching inaccessible areas and to survey the surrounding areas during implosion. Tata Steel continues to deploy industry-leading solutions and champion the sustainability discourse.

Sanjiv Paul, Vice President (Safety, Health & Sustainability), Tata Steel, said: “We have completed an important step of safe and controlled implosions of obsolete Coke Plant facilities. This is a testimony to our commitment to operational efficiency, safety, resource optimisation and sustainable growth strategy.”

Avneesh Gupta, Vice President (TQM and Engineering & Projects), Tata Steel, said: “Tata Steel strives to be a technology and innovation leader in the steel industry, leveraging in-house capabilities and building external ecosystems. And, the successful execution of these complex implosions showcases our superior engineering capabilities.”

Tata Steel's flagship Jamshedpur plant, India's first ResponsibleSteel certified site, is among the first steel plants in Asia and the only facility in India to produce steel at the same site continuously for over 100 years. The plant, recognised as a Global Lighthouse by World Economic Forum for adopting Industry 4.0 technologies, is a national benchmark in sustainability. Tata Steel's sustainable growth has been driven by its operational excellence and a culture of continual improvement.

About Tata Steel

Tata Steel group is among the top global steel companies with an annual crude steel capacity of 34 million tonnes per annum. It is one of the world's most geographically diversified steel producers, with operations and commercial presence across the world. The group recorded a consolidated turnover of US $ 32.83 billion in the financial year ending March 31, 2022.

A Great Place to Work-CertifiedTM organisation, Tata Steel Limited, together with its subsidiaries, associates, and joint ventures, is spread across five continents with an employee base of over 65,000. Tata Steel has been a part of the DJSI Emerging Markets Index since 2012 and has been consistently ranked amongst top 10 steel companies in the DJSI Corporate Sustainability Assessment since 2016. Besides being a member of ResponsibleSteelTM, worldsteel’s Climate Action Programme and World Economic Forum’s Global Parity Alliance, Tata Steel has won several awards and recognitions including the World Economic Forum’s Global Lighthouse recognition for its Jamshedpur, Kalinganagar and IJmuiden Plants, and Prime Minister’s Trophy for the best performing integrated steel plant for 2016-17. The Company, ranked as India’s most valuable Metals & Mining brand by Brand Finance, featured amongst CII Top 25 innovative Indian Companies in 2021 and top 10 sustainable organisations of India Hurun Research Institute in the 2021 Capri Global Capital Hurun India Impact 50, received Steel Sustainability Champion recognition from worldsteel for five years in a row, ‘Most Ethical Company’ award 2021 from Ethisphere Institute, RIMS India ERM Award of Distinction 2021, Masters of Risk - Metals & Mining Sector recognition at The India Risk Management Awards for the sixth consecutive year, and Award for Excellence in Financial Reporting FY20 from ICAI, among several others.

To know more, visit www.tatasteel.com and www.wealsomaketomorrow.com.

Disclaimer

Statements in this press release describing the Company’s performance may be “forward looking statements” within the meaning of applicable securities laws and regulations. Actual results may differ materially from those directly or indirectly expressed, inferred or implied. Important factors that could make a difference to the Company’s operations include, among others, economic conditions affecting demand/ supply and price conditions in the domestic and overseas markets in which the Company operates, changes in or due to the environment, Government regulations, laws, statutes, judicial pronouncements and/ or other incidental factors.

Sarvesh Kumar

Chief, Corporate Communications

Tata Steel

E-mail: sarvesh.kumar@tatasteel.com