Successfully running a manufacturing organization is no walk in the park. We know a fair bit of this challenge. From Maintenance, to Health and safety, Environment, Regulations, Technology and Unions. It definitely is not meant for businessmen who want to make quick buck. It is about Industrialists, communities and legacies. Who can recognize this better than us?

It is time that manufacturers, small and big, began sharing, learning and impacting each other. Tata Steel Industrial Consultancy (TSIC), is Tata Steel’s maiden foray in the Industrial consulting space, where our goal is to co-create Solutions to complex problems of Strategic and tactical nature, leveraging on more than a century of experience of successfully running India’s First Mega factory and evolving into a Light House of Indian Industry today.

- We are resolute practitioners, transforming to be passionate consultants

- With subject matter experts who have delivered results in an industrial context

- We co-create solutions, customized based on your needs

MANUFACTURING PROCESS ENHANCEMENT

From being pioneers of Indian Steel industry to imbibing a culture of continuous improvement in all our operations and support services, Tata Steel has come a long way. Winning numerous awards including the Deming Grand Prize and Industrial Lighthouse award (by World Economic Forum) have been a testimony to our commitment for operational excellence. It is now imperative that we make our peers partners in our success story and share some of our industry leading practices in Iron and Steel Making operations.

Process Enhancement - Ironmaking

- Drive improvement in productivity, cost, quality, safety and equipment life in your Ironmaking units

- Level II automation in Pellet and Sinter plants

- Coke plant and Sinter plant digital twins

- Blast furnaces

- Burden charging recommendation system

- Hearth life monitoring and management system

- Copper stave health monitoring and maintenance

- Online Condition Monitoring for torpedo ladle

- Site specific value-in-use (ViU) models for optimal selection of raw materials

Process Enhancement – Steelmaking

- Improve strike rate, yield and reduce rejections in your steel making operations :

- Defectology

- Through process chemistry control and optimization

- Designing the least cost and most effective alloying scheme for achieving a specific chemistry

- Automation solutions

- Level II automation system for BOF

- Caster breakout detection system

- Real time billet Rhomboidity measurement

- Surface Quality Inspection Systems

- Process Safety Dashboards

Process Enhancement – Plant Infrastructure

- Improve the effectiveness of your infrastructure through our Technology based solutions

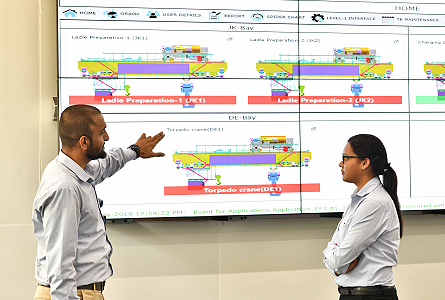

- Torpedo ladle tracking system

- Automated Yard Management System

- Centralized equipment condition monitoring system

- Stack emission plume dispersion monitoring system

Tata Steel has a long history of exploration and mining. It has therefore developed an expertise in all aspects of mining – from exploration, resource evaluation to mine planning & scheduling and quality control and monitoring. Given the extreme competition for mining resources – it is extremely critical to make an accurate assessment of the exploration data and build a robust business proposal. The increasing regulatory oversight in the industry necessitates having deep technical expertise which allows for creating a mining plan that is sustainable and delivers to the expectations of quality and throughput. Following are some of the key services offered by TSIC under exploration and mine planning:

- Exploration and logging

- Resource Modelling

- GR Preparation

- Mine Design

- Mine Production and Quality Scheduling

- Tecno-commercial study

- DGPS survey and geo-referencing

- Drone based survey

Tata Steel through its journey of continuous improvement has built several business process capabilities that are relevant not just for the steel industry but for all organizations to improve profitability through improving quality, productivity and cost management. TSIC offers its client access to capabilities in the following areas:

- Total Quality Management (TQM)

- Total Productive Maintenance (TPM)

- Industrial Engineering

- Business Process re-engineering

- Supply Chain Optimization

- Facility Layout & Material Flow Optimization

- Simulation and Analytics

- Business process excellence – an improvement framework aimed at achieving best in class profitability

Effective human resource management and harmonious industrial relations are key for the success of any business. A motivated and engaged workforce are vehicles for driving performance and are a key pillar of support in challenging business environments. Over the years Tata Steel has developed an expertise in designing policies, participating in wage negotiations and revisions and establishing a unique joint consultative mechanism that have helped nurture a harmonious, performance based, work culture amongst its employees. Our excellence in human resource management is testified by numerous awards including winning the ‘best places to work’ award several times in past years.

TSIC offers the rich experience of Tata Steel in human resource and industrial relations to promote a rich and robust work culture across industry sectors. Our services include:

- Implementing best practices in compensation & benefits (total rewards framework) and social security schemes

- Organizational restructuring, policy design

- HR integration

- Diversity & Inclusion

- Legal advisory, understanding labor codes and its implications

- We also invite you to undertake a unique journey of IR excellence –a Joint Consultative Mechanism where both management and union work together to achieve the goals of your organization

Corporate

Corporate

Sustainability

Sustainability

Products & Solutions

Products & Solutions

Investors

Investors

Careers

Careers

Contact Us

Contact Us

Eligibility

Eligibility Rules

Rules Rewards

Rewards Contact Us

Contact Us