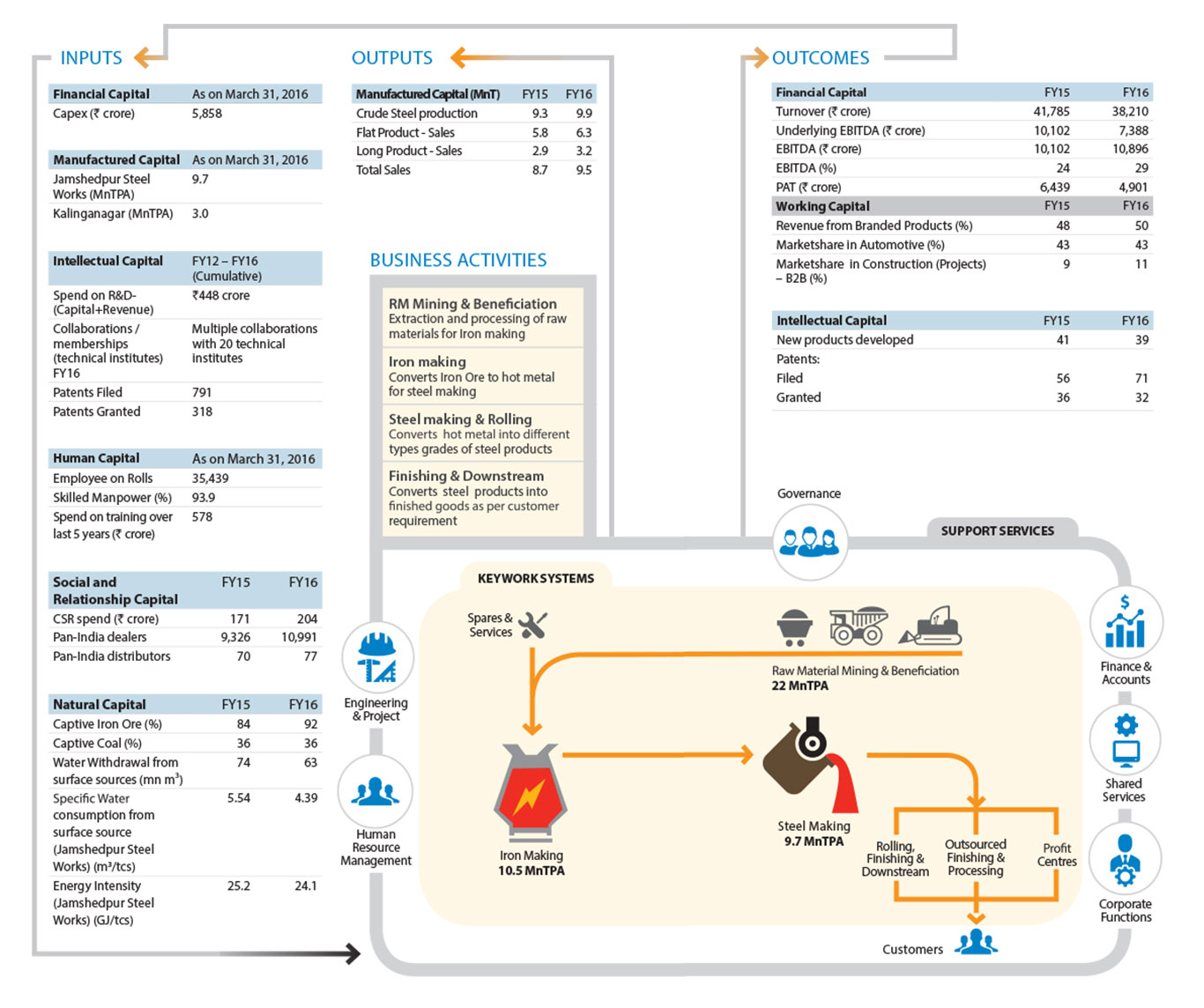

Our value creation process comprises converting heterogeneous raw materials (Iron ore and coal) into customised steel products for customers.

At the core of our value creation process is the business model which represents a well-integrated steel manufacturing operation from mining to steel making and further downstream processing.

We produce outputs (Flat and Long steel products and solid waste as a by-product), while drawing inputs from the various capitals. Our business activity endeavours to minimise the negative environmental and social impacts and to enhance our competitive position, relationships, brand image and reputation.

The outcomes of the business activities on the various capitals are shown in the business model. The Company measures these outcomes at defined frequencies and takes suitable actions to improve them, while maintaining a strategic focus on long-term value creation for all stakeholders.

The vision, mission, values, our systems & process approach and longterm relationship with stakeholders is at the very core of our operations that leads to sustainability of our business.

Fundamental to our activities and processes is the culture of innovation and continuous improvement to generate new products to meet our customer requirements. Our goal is to leverage best available technologies, improve resource efficiency, increase solid waste utilisation and make products and processes more environment friendly.

We are unique in not just the magnitude of our operations but also in our people practices, our innovative approach and our overall conduct.

| Human Capital | FY15 |

FY16 |

| Fatality | 5 |

2 |

| LTIFR Index | 0.31 |

0.23 |

| Health Index | 12.21 |

12.35 |

| Attrition Rate (%) | 3.57 |

4.47 |

| Employee Productivity (tcs/FTE) | 623 |

701 |

| Diversity – Women (%) | 5.36 |

5.50 |

| Natural Capital | FY15 |

FY16 |

| Water discharged after use (mn m3) | 27 |

14 |

| Water discharged after use (Jamshedpur Steel Works) (m3/tcs) |

2.3 |

1.2 |

| Solid waste Utilisation (%) (Jamshedpur Steel Works) |

78 |

81 |

| Dust Emission (Kg/tcs) (Jamshedpur Steel Works) |

0.57 |

0.5 |

| GHG Emissions (Direct + Indirect) (Jamshedpur Steel Works) (tCO2/tcs) |

2.42 |

2.26 |

| GHG Emissions (Direct scope-1) (Jamshedpur Steel Works) (tCO2/tcs) |

2.26 |

2.11 |

| Tree Plantation (mn) | 0.3 |

0.4 |

| Biodiversity | Biodiversity assessment caried out in 8 Raw Material locations in FY16 and Corporate Biodiversity Policy launched |

|

| Social and Relationship Capital | FY15 |

FY16 |

| Lives Impacted (mn) | 1.3 |

1.1 |

| Affirmative Action (% Employed) | 16.3 |

16.9 |

| Manufactured Capital |

| Jamshedpur |

| Best-ever performance, % increase over FY15: Sales: 9.54 MnT, 9% increase Crude Steel production: 9.97 MnT, 7% increase Hot Metal production: 10.65 MnT, 4% increase |

| In our continuing efforts towards efficiency improvement, the Blast Furnaces in Jamshedpur achieved best-ever coke rate and highest best-ever coal rate (Indian Benchmark) |

| Environment clearances received for Jamshedpur plant expansion to 11 MnTPA Crude Steel |

| Kalinganagar |

| Production started at the 3 MnTPA Kalinganagar Steel Plant (currently under stabilisation). This will significantly improve volume growth and expand our product portfolio in the L&E, Ship Building, Defence Equipment, Energy & Power, Infrastructure and Aviation sectors. |

| Ferro Alloys and Minerals Division |

| After clearances from Regulators, our FAMD production has been ramped up in FY16 |

| Gopalpur ferrochrome plant to come on board with ~55,000 TPA in FY17 |