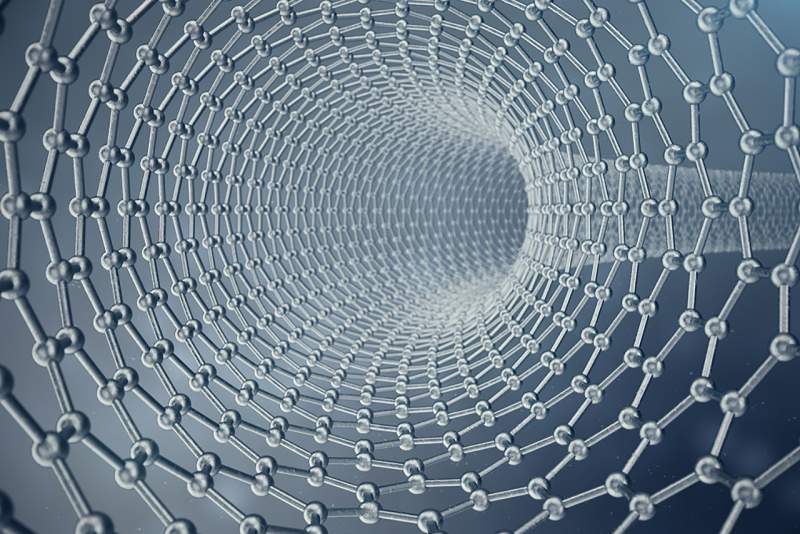

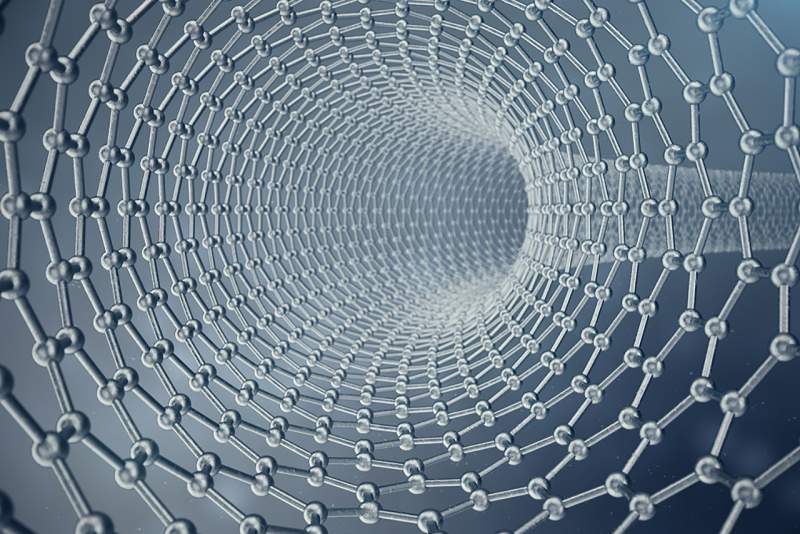

Here's a little background about graphene and its applications that have the potential to revolutionise many sectors. While it is the thinnest material in the world, it is 300 times stronger than steel. It is flexible, transparent and waterproof. MIT researchers have found graphene to be a superconductor. Researchers in Australia have found graphene to be a powerful filtration material. Graphene has the potential to be utilized in energy, membranes, composites and coatings, biomedical sensors. The material can replace carbon fiber, steel, and aluminum components in a car, making it lighter and more fuel-efficient. The material can be utilised to make lighter planes and space shuttles as well.

That's a huge list of 'what could be'. Now the next logical question arises: If graphene is so awesome, why isn't it used everywhere? The answer is a simple one. At $100/gram, it is as expensive as a supermaterial can be, which makes it a little difficult to produce.

Fortunately, there are advances being made in the field of graphene research around the world to produce it on a larger scale. A team of physicists from Kansas State University have discovered a way to mass-produce graphene using hydrocarbon gas, oxygen and a spark plug. The team includes two scientists of Indian origin: Arjun Nepal, a postdoctoral researcher and instructor of physics, and Gajendra Prasad Singh, a former visiting scientist.

They are not the only Indians heavily invested in the production of this material. Closer to home, Tata Steel is leading graphene research in India.

Sumitesh Das, Chief, Graphene Business, Tata Steel is very gung-ho about graphene. He believes graphene will first change the wearables space. He says, “If you can put a coating of graphene on paper or fabric, and pass electricity through it, you have created a heater. We are in cold places all the time: either in cold climates or in an Uber or an air conditioned space. You run this on a 5V power supply.” Graphene can create heaters immediately. Boom! The cold problem just got solved. Tata Steel is already working on concepts like these.

A graphene development cell has been set up by Tata Steel in Jamshedpur to identify new applications of graphene and establish new businesses (production units, supply chain and markets). Material research centers have been established in Chennai (in collaboration with IIT) and in Bangalore (in collaboration with the Center for Nano and Soft Matter Sciences).

Tata Steel is working on three major areas in the graphene space. The first one is making sure that the yield from the raw material is optimum. What's a good raw material for graphene? “Anything from flowers to petals to bread that we eat daily”, says Sumitesh Das. The second area is synthesizing graphene. How do you get graphene into a particular composite or a solution in order to make sure it works smoothly? The third area is the end of life for graphene products. The best brains at Tata Steel are working on how to discard it with zero pollution.

Graphene products by Tata Steel are already out in the market. In August 2017, the company launched ready-made graphene-coated stirrups, named Tiscon Superlinks+. The stirrups have enhanced corrosion resistance and better bonding strength than similar products in the market. The Graphene Development Centre has also produced corrosion-resistant graphene paint and supplied graphene powder to tyre companies. Next in line for Tata Steel is Gink or graphene inks.

Graphene has the potential to revolutionise every sector, from aviation to biomedical. As with every revolution, it starts slow, but it is only a matter of time before it changes everyone's lives for the better. Here's hoping to a better tomorrow!

Corporate

Corporate

Sustainability

Sustainability

Products & Solutions

Products & Solutions

Investors

Investors

Careers

Careers

Contact Us

Contact Us