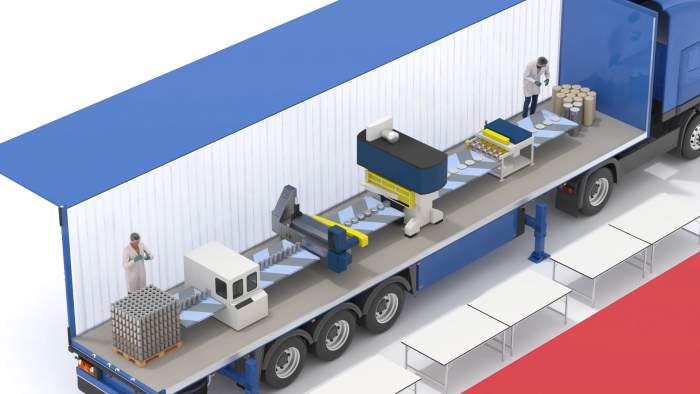

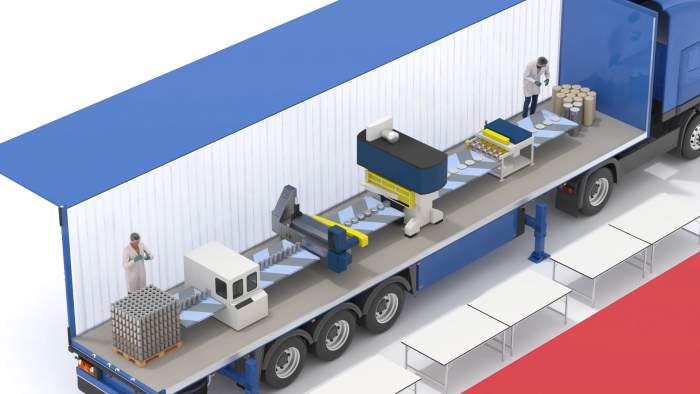

Which is why we're so excited about Tata Steel's Mobile Canning solution! What started out as an attempt to further streamline the canning production line, has grown into a truly future facing project. Tata Steel's Protact® laminated steel was the starting point - the three-layer polymer coating system on Protact® results in a canning process that is five whole steps shorter, and one that uses no water. Now that they had a shorter process, they decided to refine it some more, and see if they could take it out of the factory itself. The result? Tata Steel's Mobile Canning trucks.

No, you read that right! Two trucks - one that produces the cans onsite from Protact® disks, and another that fills the cans with produce, and then seam, sterilise and label them as well! Quality control is built in: produce is sorted, cleaned, prepared for canning, and must pass the final visual inspection before being filled into cans. The trucks are self-powered, and as there is no water involved in the can making process, there are no external dependencies that can trip up the operation. The mobile trucks can roll up to the farm itself, produce the cans, then can the produce, and move on to the next farm. Simple.

Obviously, this is a game changer for farmers. Not only can they prevent spoilage and protect their income, they can also gain valuable skills. Canning serves as a gateway to other, more value-added methods of preservation. Moreover, it will give them their power back - they will be able to ride out price fluctuations once spoilage isn't an issue, and they won't have to rely on the expensive and often exploitative transportation and storage provided by middlemen! Bumper harvests will finally be a cause for real celebration. With increased incomes, farmers could also explore creating their own cooperatives: capex will be low, as basic storage sheds and open trucks will do just fine for canned goods.

Should we see increased adoption, it will offer a unique opportunity for the Government to introduce vegetables and fruit into the public distribution system. It will also go a long way in augmenting farmer income (which by itself helps with socio-economic issues like income disparity and urban migration) and support the move from producing food grains to growing more profitable horticulture crops.

For consumers like us, this could mean preservative free, quality checked vegetables and fruit that have higher nutritive value than those we see in our local mandis... at stable prices. And we get to enjoy a greater variety all year round!

Environmentally speaking, Mobile Canning is a brilliant idea: overall reduction in the use of preservatives (for transportation and storage of "fresh produce"), which means fewer chemicals in the ground and in our water. There's no water used during can production, no volatile organic compounds emissions, and the cans themselves are fully recyclable. This, of course, fits in perfectly with Tata Steel's vision of sustainability, and we see clear evidence of the careful thinking that has gone into every stage of this project.

This is one of those times when technology and corporate will have come together to create a world of good. The pilot for this project was successfully launched in Europe. This is why Tata Steel is actively seeking engagement with different parties in the supply chain to bring this concept alive in India. The aim is that two years from now, the mobile canning trucks hit the markets, they will present an invaluable opportunity to Governments and grocery chains alike to bring prosperity to farmers. They will aid in vastly improving the quality of produce available to end customers. This tailor-made solution for Indian conditions, can easily be adopted in other parts of the world that have similar constraints.

We live in an age of rapid technological disruption, and the sky really is the limit. Socially minded businesses hold the answers to the world's biggest problems through their investments in technology that serves the greater good. A country like India presents a unique opportunity for businesses to find solutions that not only further their own economic objectives, but leapfrog the nation as a whole towards greater progress. The reason why mobile canning is being looked upon as a perfect solution, is because it truly resonates with Tata Steel's endeavors of making a better and brighter tomorrow. It represents a step in the right direction, which will help create a tomorrow that is fueled by technological innovations... innovations that empower every segment of the population and aid to the vision of India's bright future.

Corporate

Corporate

Sustainability

Sustainability

Products & Solutions

Products & Solutions

Investors

Investors

Careers

Careers

Contact Us

Contact Us