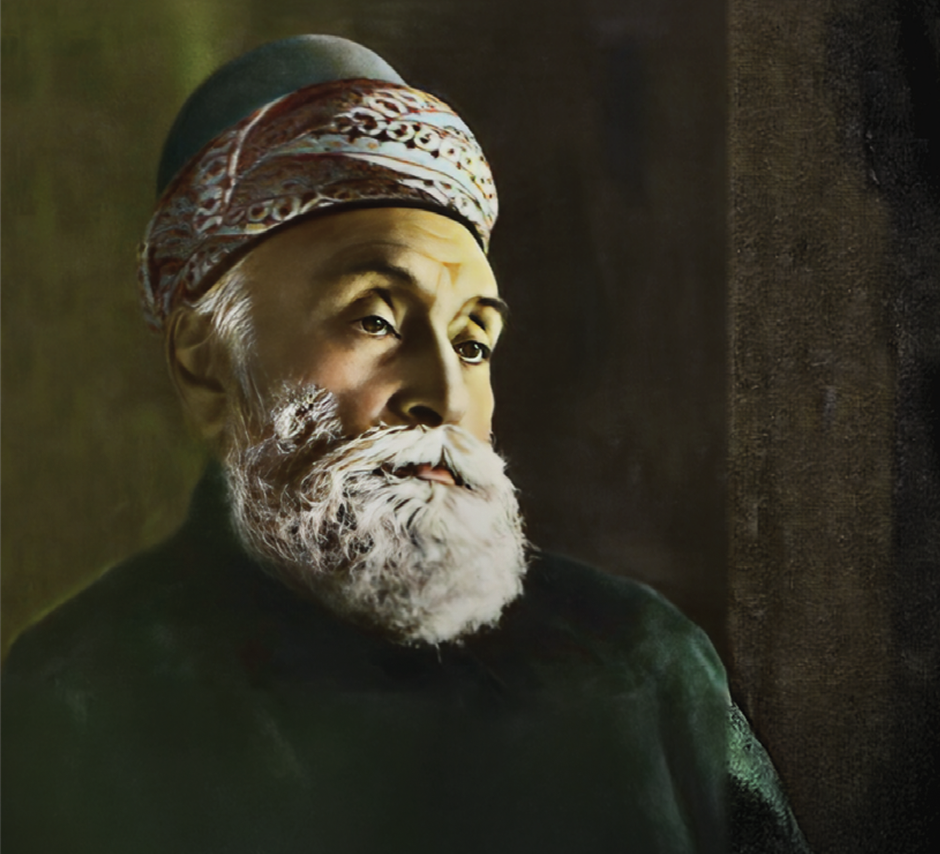

Remembering Mr Tata

Padma Vibhushan

Ratan N Tata

December 28, 1937 - October 9, 2024

It is with a profound sense of loss that we bid farewell to Mr Ratan Naval Tata, a truly uncommon leader whose immeasurable contributions have shaped not only the Tata Group but also the very fabric of our nation.

Diversity in all job categories

Lives reached

Recordable injuries and harm

Tata Steel Group