New products developed

Patents granted

Tata Steel collaborates with academia, industry, and startups to pilot and deploy solutions. Significant digital investments and AI-driven tools support business continuity, safety and decision-making. A culture of continuous improvement drives new benchmarks across the value chain.

Intellectual Capital

Emerging as an IP powerhouse

In FY2024-25, Tata Steel actively advanced its innovation strategy by filing more than 170 patent applications across several key jurisdictions, including but not limited to India, the UK, and the European Patent Office. Tata Steel's strategic focus is centred on three critical areas: the development of high-strength steels, sustainability initiatives, and advancements in coatings technology. By prioritising these domains, Tata Steel aims to not only strengthen its IP portfolio but also drive innovation that aligns with evolving market demands and environmental considerations.

Tata Steel was recognised at the CII Industrial IP Awards 2024, winning the Best Patent Portfolio Award in the Large Manufacturing/Engineering category. Its IP excellence was further highlighted in the Indian Patent Office's Compendium, which showcased patents aligned with the United Nations Sustainable Development Goals – 8 of the 80 featured patents belonged to Tata Steel.

Further reinforcing its leadership, Tata Steel was honoured with the National Intellectual Property Award and the World Intellectual Property Award for being the top Public/Private Company in India in Patent Filing, Grant, and Commercialisation.

Product Development Centre, Jamshedpur

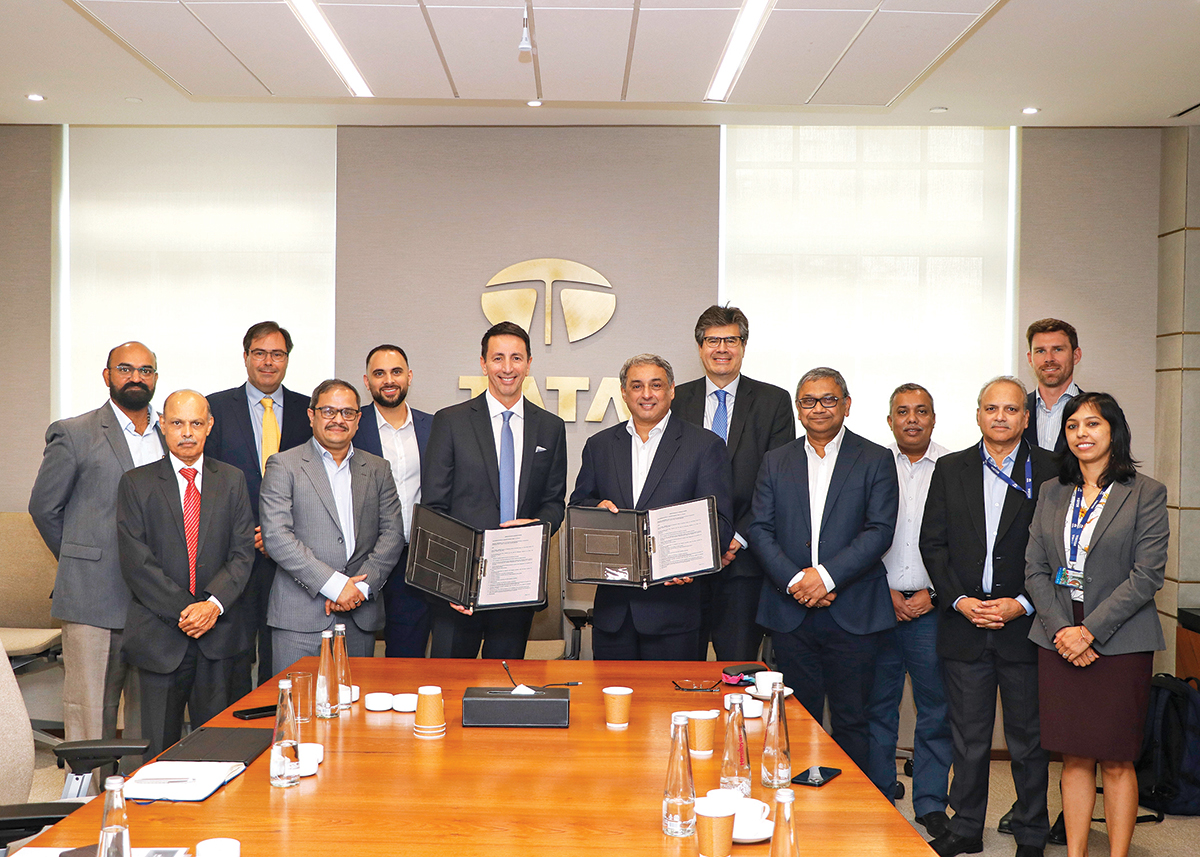

MoU with Monash University

Key developments

Waste Heat Recovery (WHR) and Utilisation

Waste Heat Recovery (WHR) and Utilisation is a significant contributor in improving process efficiency and delivering cost savings. As part of its efforts to explore breakthrough WHR solutions, Tata Steel engaged with Kraft Block GmbH, a German start-up that offers eco-friendly and modular thermal energy storage systems. Following an extensive evaluation of 14 potential sites based on temperature, waste heat availability, process integration, space, and engineering feasibility, the Kraft Block technology was implemented at one of its Sinter Plants at Jamshedpur, accelerating the sintering rate.

Unlocking value from low-grade manganese ores

Manganese is critical in steelmaking for its strength-enhancing properties and is increasingly valued in battery production due to its cost-effectiveness and wide availability. Tata Steel extracts value from low-grade manganese ore (Mn<35%) and sub-grade ferruginous manganese ores (Mn<25%) through leaching under specific hydrometallurgical conditions to produce manganese sulphate free from iron impurities, which can be further refined for battery applications. Additionally, through electrowinning, manganese sulphate can be converted into Electrolytic Manganese Metal (EMM), and with minor adjustments to cell design, Electrolytic Manganese Dioxide (EMD). Tata Steel has recently commissioned India’s first indigenous pilot plant capable of producing 25-50 kg per day of EMM and EMD, leveraging this innovative processing technique.

Centre for Innovation on Environment and Intelligent Manufacturing

Monash University and Tata Steel have signed an MoU to establish a Centre for Innovation on Environment and Intelligent Manufacturing, aimed at addressing global challenges such as decarbonisation, sustainable resource recovery, and smart manufacturing technologies. This marks Tata Steel’s first major R&D collaboration with an Australian institution, leveraging Monash University's expertise in material science and advanced manufacturing.

Shikhar25

Shikhar25 is a multi-dimensional and cross-functional programme aimed at improving EBITDA through structural changes that drive operational efficiency, process improvements, product mix optimisation, waste reduction and recycling, energy efficiency, and revenue maximisation across the value chain. The process benchmarks operating performance indicators and identifies key enablers to achieve best-in-class yield, energy efficiency, throughput, quality, and cost.

In FY2024-25, Shikhar25 helped Tata Steel reduce cost through performance improvement initiatives, some of which are given below.

Key improvements for FY2024-25

- Reduction in SRM (Store Repair and Maintenance) spend by ₹834 crore

- Reduction in General Administration and General Works (GAGW) spend by ₹508 crore

- Increase in domestic clean coal production: ₹192 crore

Sustainable Process Research and Innovation Centre, Jamshedpur

Industry 4.0

Tata Steel has significantly invested in cloud, data, and AI as strategic enablers within a framework driven by value and clear impact on Business KPIs. The fundamental part of the strategy is data quality, and to be able to capture and curate data needs.

Tata Steel has established a secure, multi-tenant cloud platform and connected enterprise-wide systems to standardise processes across geographies, enabling alwayson operations, cost efficiency, and organisational agility. With significant investments in sensors and systems, the Company now curates 11.2 petabytes of global data, using automation to deliver a ‘single version of truth’ across critical KPIs, including cost and wage metrics.

Over the past 5-6 years, the Company has built over 588 AI models with deep focus on generative and mathematical AI, unlocking advanced insights, conversational interfaces, and complex problem-solving capabilities.

~75% of AI models enhance Manufacturing Excellence, driving improvements in yield, energy efficiency, throughput, quality, productivity (YETQP), and safety. Tata Steel has developed Operations and Machine Twins that enable remote and intelligent operations, maintenance, and mining.

Tata Steel enables functional excellence in areas such as HR, Procurement and Finance. Its investments in supply chain and logistics have modernised its backend processes. Initiatives such as the smart indenting system under its spares, repairs and maintenance programme enable notable cost savings.

Enhancing Customer Experience is a key focus, with ~₹500 crore in monthly online sales on its digital platforms. ~20% of its AI models are focused on enhancing customer experience, customer interactions, complaint resolution and satisfaction.

The Company's Digital and AI-led transformation, aligned to the Shikhar Value Framework, has delivered tangible value.

Today, 80% of our steel production comes from WEF Global Lighthouse sites, and Tata Steel has been recognised as an Advanced Leader in Digital by Gartner for 4 years consecutively.

Investment in Technology Infrastructure

Tata Steel consistently invests in technology infrastructure, reinforcing its commitment to innovation. Key developments include the High-Performance Computing Cluster (HPCC), Product Development Centre (PDC), and Sustainable Process Research and Innovation Centre (SuPRICe).

The HPCC, equipped with 1,208 CPU cores, 14 GPU cores and 576 TB storage, enables high-end simulations such as computational fluid dynamics, finite element modelling, and AI/ML applications, accelerating product and process innovation. The PDC offers a state-of-the-art physical simulation environment, featuring a fully operational high-end vacuum steelmaking unit and plans for rolling operations. Its capabilities position it amongst the best global R&D labs. The SuPRICe Lab focuses on solutions for iron and coke making.

Total Quality Management (TQM)

To support future growth, the Company introduced a ‘Plug and Play’ framework to streamline quality implementation at new sites. Phase I of the TQM plan was launched across all Tata Steel locations in India, achieving 97% shop floor involvement. With a focus on ‘Customer Experience’, Tata Steel enhanced quality awareness and extended this culture to suppliers and contract employees. The ‘Quality Board’ was revamped to include an external advisor, and unified metrics such as Cpk were introduced. Key projects included the Agile Customer Complaint Management System, elimination of Rank A claims at Meramandali, and Quality Function Deployment with an automaker at Sahibabad.

Apex TQM Awards Nite 2024

To drive business improvements through analytics, over 9,000 improvement projects under the ASPIRE programme were implemented using Six Sigma, TOC (Theory of Constraints) and CCPM (Critical Chain Project Management) methodologies. On the shop floor, 3,750 kaizens were completed, with 4,205 quality circles active. Three MASS waves focused on spillage reduction, consumable usage, and mistake-proofing. The Total Productive Maintenance (TPM) gained traction, improving Overall Equipment Effectiveness (OEE) by 2% in the bottleneck areas across Kalinganagar, Meramandali, and Raw Material locations. Tata Steel Gamharia received the prestigious JIPM excellence award for successful implementation of the first level of TPM practices.

Tata Steel was recognised as one of India’s top 20 most innovative companies by the Confederation of Indian Industry (CII) at the Industrial Innovation Awards 2024. At the Tata InnoVista Awards 2024, the Company achieved significant success, securing four (Tata Steel Limited – 3, Tata Steel Nederland – 1) out of 16 awards in categories like ‘Product and Service Innovation’ and ‘Most Innovative Partner’.

Over 6,500 employees were trained to build TQM capabilities and 115 subject matter experts were developed.

At the Tata Group level, Tata Steel facilitated seven best practice-sharing sessions and was also recognised as the ‘Most Engaged Company in Improvement Interventions’ at the Tata Business Excellence Convention. Tata Steel actively engaged in learning and sharing best practices with the IFQM (Indian Foundation for Quality Management) fraternity and participated in learning missions with the member companies. Tata Steel also contributed to the IFQM Academy curriculum and curated the digital roadmap to elevate MSMEs.

Tata Steel's shop floor teams excelled at the 49th International Convention on Quality Control Circles in Colombo, winning the fifth consecutive ‘Gold’ award. Additionally, 38 teams from Tata Steel participated virtually in the 38th National Convention on Quality Concepts 2024, out of which 68% earned the 'Par Excellence' award.

In the Netherlands, operational performance has improved through the Cost of Poor Quality and Reliability programme. At Tata Steel UK, the Enterprise Process Model (EPM) framework is being assessed to better meet the operational requirements of low-emission steel production. A standardised approach to ‘Problem Solving and Investigation’ has been developed for rollout. Tata Steel Thailand completed Step 3 TPM audits at all three plants, achieving an impressive steel plant run factor of 94.91% at SISCO.