Report Menu

Report Menu

STRATEGY

Roadmap to future

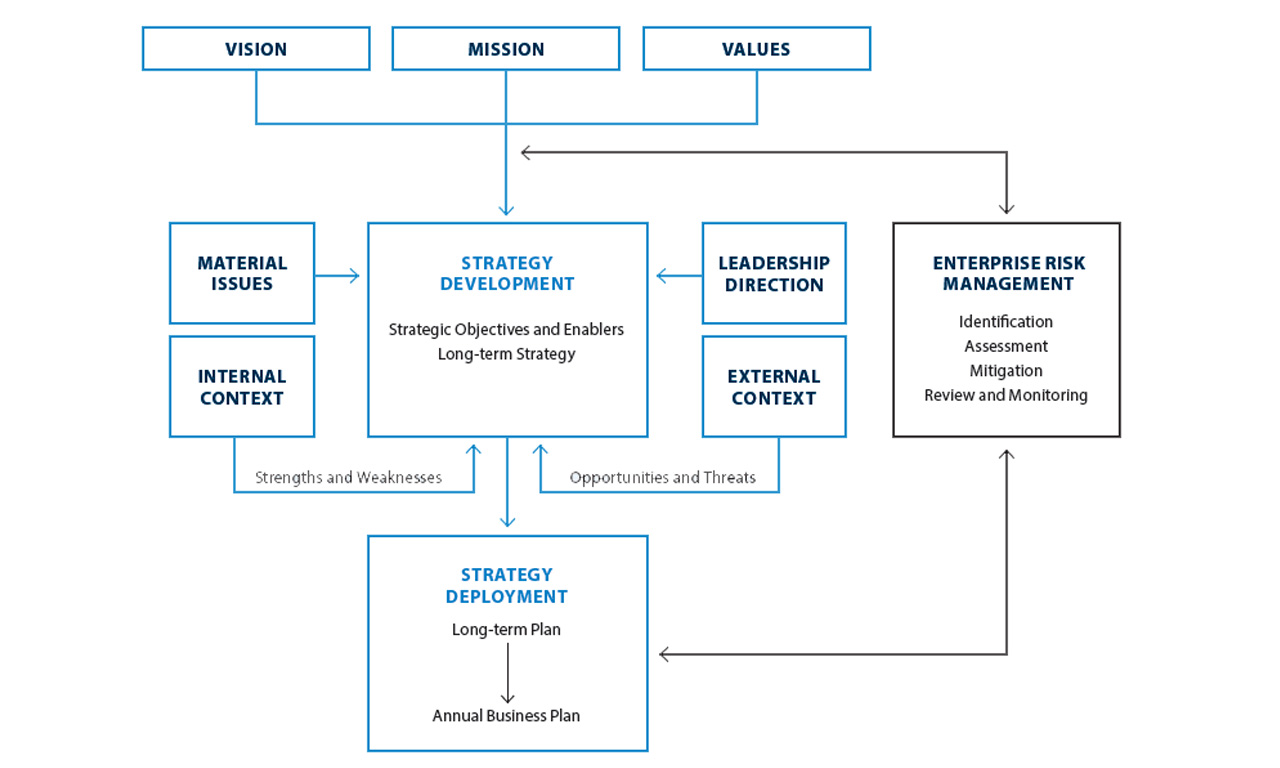

As part of our strategy planning process, we scan the external environment for megatrends and understand how these trends influence the steel sector. We identify the risks and opportunities that could disrupt the industry. Materiality assessment provides further insights to the changing needs of all our stakeholders.

Our integrated strategy planning process drives strategy formulation and implementation across the short to long-term horizon.

Strategy planning process overview

While Tata Steel has consistently been one of the most profitable and lowest cost producers of steel1 in the world, the Company needs to address challenges such as improving productivity, maintaining cost competitiveness, and being agile and innovative in a rapidly evolving business environment.

Tata Steel aspires to further strengthen its leadership position, and for this purpose, has defined a set of Strategic Objectives (SOs). To achieve the SOs, we have also identified a set of core capabilities, known as ‘Strategic Enablers’.

Strategic Objectives

- SO1

INDUSTRY LEADERSHIP IN STEEL

Scale of operations is a pre-requisite for steel industry leadership.

- SO2

CONSOLIDATE POSITION AS A GLOBAL COST LEADER

We aspire to be a global benchmark in operational efficiency, ensure raw material security and strengthen our logistics network.

- SO3

INSULATE REVENUES FROM STEEL CYCLICALITY

The steel industry is cyclical in nature. It is essential to build a portfolio of products and services that can provide protection from cyclicality and lend stability and momentum to our revenues and profitability.

- SO4

INDUSTRY LEADERSHIP IN CSR AND SHE

We aspire to be a leader in sustainable business practices. As a responsible organisation, we are committed towards creating and providing a safe working environment for our people, carrying out environment-friendly business operations and improving the quality of life of the communities we operate in.

Strategic Enablers

EMPLOYER OF CHOICE

People are key for an organisation aspiring to strengthen its leadership position, and being an employer of choice is a significant aspect of our strategy.

LEADERSHIP IN STEEL TECHNOLOGY

To prepare for disruptions in the future, our ability to innovate and develop new products, improve processes, develop technologies and transform business models is critical.

AGILITY AND INNOVATION

It is essential to focus on creating the right organisational culture that encourages agility and innovation.

LEVERAGE DIGITAL TECHNOLOGY

Digitalisation is critical for attaining technology leadership in the Industry 4.0 era and drive innovation.

1Comparison of cost is done at crude steel level

Our strategic goals and performance

- SO1

INDUSTRY LEADERSHIP IN STEEL

Panview of State-of-the-art Kalinganagar Steel Plant

Focus areas

- Capacity expansion of domestic operations through organic as well as inorganic routes to meet growing customer demands and aspirations

- Maintain leadership position in chosen segments

Key Performance Indicators (KPIs)

- Crude steel capacity

- Market share

Goals

30 MnTPA

in India, by 2025

Sustain #1 position

in chosen segments

- SO2

CONSOLIDATE POSITION AS A GLOBAL COST LEADER

Iron Ore, Noamundi Mine

- Continue to invest in raw material security

- Cost improvement and value enhancement through Shikhar25 continuous improvement programmes

- Captive coal (%) and Captive iron ore (%)

- Value accrual

Maintain cost leadership at market price of raw materials

Improved cost and value enhancement

SO1 - Industry leadership in steel

SO2 - Consolidate position as a global cost leader

SO3 - Insulate revenues from steel cyclicality

SO4 - Industry leadership in CSR and SHE

- SO3

INSULATE REVENUES FROM STEEL CYCLICALITY

‘AquaNest’ - Water Vending Kiosk, Nest-In

Focus areas

- Services & Solutions business

- Downstream products (e.g. Cold Rolled, Tubes, Wires, Bearings)

- B2C Business

- New materials business

‘Pravesh’ Steel Door

Key Performance Indicators (KPIs)

- Revenue (% of total revenue)

- Volume (% revenue)

- Volume (% revenue)

- Revenue from new materials (% of total revenue)

‘Nestudio’ - A Steel-based Smart Housing Solution

Goals

Increase revenue from services and solutions business

Improve downstream products business

Enhance volume in B2C business

Increase revenue from new materials business

- SO4

INDUSTRY LEADERSHIP IN CORPORATE SOCIAL RESPONSIBILITY AND SAFETY HEALTH & ENVIRONMENT

3 MW Solar Power Plant, Noamundi Iron Mine

- Achieve leadership in safety

- Become a benchmark in CO2 emission

- Reduce water consumption

- Create value through circular economy: LD slag utilisation and steel recycling business

- Create lasting impact on the communities in our operating areas

- Fatality, Lost Time Injury Frequency Rate (LTIFR)

- CO2 emission intensity

- Specific water consumption

- % of LD slag utilisation and Capacity (MnT) of scrap recycling business

- Number of lives impacted

Zero fatality

< 2tCO2/tcs by 2025

Zero effluent discharge by 2025

Sustain LD slag utilisation at 100% and enhance capacity of scrap recycling business

>2 Mn lives by 2025