- Greenhouse Gas Emissions and Climate Change Management

- Circular Economy/ Recycling of By-products

- Water Consumption and Effluent Discharge

- Energy Efficiency/ Energy Management

GR  WTH

WTH

WITH PURPOSE

Performance Snapshot FY2022-23

Demonstrating resilience

Despite a challenging global business environment for the steel industry, Tata Steel had a record-breaking operational performance in India, in FY2022-23. We achieved the highest-ever annual production and deliveries, driven by our strong marketing network and agile business model.

- Tata Steel (India)1

- Tata Steel

(Consolidated)

Production2

(MnT)-

4%

0

-

1%

0

Deliveries

(MnT)-

3%

0

-

2%

0

Turnover

(` crore)-

0.9%

1,0

-

0.2%

2,0

Reported EBITDA

(` crore)-

48%

0

-

49%

0

Adjusted EBITDA/tonne

(`)-

53%

0

-

53%

0

Reported PAT

(` crore)-

61%

0

-

81%

0

2 Production Numbers: Standalone & Tata Steel Long Products –

Crude Steel Production, Europe – Liquid Steel Production; SEA – Saleable Steel

Production

1 Tata Steel (India): Standalone & Tata Steel Long Products

Contribution to UN SDGs

Embracing shared goals for sustainable development

Embracing the global call for holistic development for people and the planet, we, at Tata Steel, have aligned our operations and CSR activities with the United Nation’s Sustainable Development Goals to ensure a better future.

Chairman's Message

Demonstrating strength and resolve

The Company has made substantial progress in its simplification journey and is working on the amalgamation of seven subsidiaries and one associate company into and with Tata Steel.

Read moreBusiness Model

Fuelling progress

Inputs

Financial Capital

Consolidated Net worth – Total Equity (₹ crore) 1,05,175

Consolidated Net debt (₹ crore) 67,810

Manufactured Capital

Region wise Installed capacity - Crude Steel in MnTPA

India 21.6

Europe 12

South East Asia 1.7

Steel Processing Centres and downstream

facilities - Own (Nos)1 40

Intellectual Capital

Patents filed (nos.) 154

R&D spend (₹ crore) 859

Human Capital

Employees on roll (nos.)9 77,000+

Investment in employee training and Development (₹ crore)1 193

Employee training (thousand person-days) 519

Natural Capital

Energy Intensity (GJ/tcs)11

TSL 23.43

TSLP 41.06

TSUK 23.34

TSN 18.82

TSTH 5.06

Specific fresh water consumption (m3/tcs)11

TSL 2.62

TSLP 5.81

TSUK2 9.84

TSN2 5.21

TSTH 1.09

Capital spends on environment, social and governance matters ( ` crore) 3,304

Raw Material consumption (MnT)3 65

Social and Relationship Capital

Total dealers (nos.) 20,478

Total distributors (nos.) 267

Active supplier base (nos.) 12,872

CSR spend (₹ crore) 481

Steel Value Chain

Mining

Total materials mined1

Processed Raw Materials

Raw materials consumed3

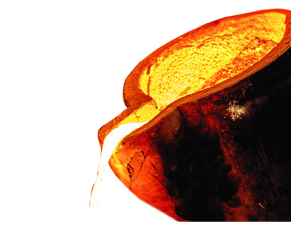

Iron Making

Production4

Steel Making

Total deliveries

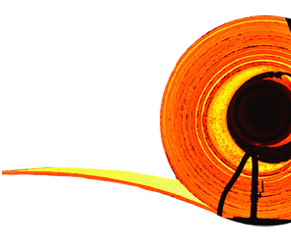

Rolling Products

Enriched/value added product sales1

Processing Centres

Number of SPCs1

Demand Fulfillment

Customer Satisfaction Index1

(score out of 100)

Enabling Functions

Supply Chain

FG handled3

RM handled3

Human Resources

Employee Productivity1:

(tcs/employee/year)

Technology

Number of Patents filled:

By-products

Revenue from by-products sale

Digitalisation

Cumulative Value Potential created through digital projects1 (FY19 to FY23):

FY2022-23

Highlights

30.65 MnT

Production4

28.79 MnT

Deliveries

11.96 MnT

Enriched/value added product sales1

Financial Capital

Turnover (` crore) 2,43,353

EBITDA (` crore) 32,698

Savings through Shikhar25 projects and Transformation Programmes (₹ crore)1 6,309

Manufactured Capital4

Region wise production (MnT)

India 19.88

Europe 9.35

South East Asia 1.2

Intellectual Capital

Patents granted (nos.) 307

New products developed (nos.) 107

Human Capital

Health index (Score out of 16) (nos.)1 13.1

Diversity - % women in the workforce5 8.3

Employee productivity - (tcs/employee/year) (nos.)6

TSL 885

TSLP 722

TSUK 352

TSN 660

TSTH 1,115

Diversity Mix (%)7, 1 18.95

LTI (nos.) 275

LTIFR (Index) 0.57

Workforce covered through formal workforce union(%)8 91

Natural Capital

CO2 emission intensity (tCO2/tcs) 2.21

Stack Dust emission intensity (kg/tcs)11

TSL 0.34

TSLP 1.30

TSUK 0.28

TSN 0.25

Solid waste utilisation (%)10 101.7

Effluent discharge intensity (m3/tcs)11

TSL 0.43

TSLP 0

TSUK2 10.02

TSN2 34.29

TSTH 0

Social and Relationship Capital

Suppliers assessed based on safety (%)

TSL 78

TSUK 100

TSN 67

Customer satisfaction index (Steel) (out of 100)1 83.8

Business associates trained on TCoC (nos.)3 2,300

Supply chain partners assessed on Responsible Supply Chain Policy (nos.)1 211

Lives reached through CSR initiatives (Mn) 3.15+

- Tata Steel Limited

- Data is for Calendar Year 2022

- Data for only Tata Steel Limited including Tata Steel Long Products Limited

- Production numbers for consolidated financials are calculated using crude steel for India, liquid steel for Europe and saleable steel for South East Asia

- Diversity - % women in the workforce is defined as percentage of permanent women employees (officers + non-officers) as per Employee on Roll (EOR) report over total workforce

- Employee productivity is defined as amount of crude steel produced (in tonnes) per employee in the given year.

- Diversity mix (% of individuals who are Affirmative Action (AA)/Women/Persons with Disabilities (PWD)/Lesbian, Gay, Bisexual, Transgender, Queer (LGBTQ+) over EOR)

Abbreviations: TSI - Tata Steel (India), NINL – Neelachal Ispat Nigam Limited, TSLP – Tata Steel Long Products, TSUK – Tata Steel UK Limited, TSN – Tata Steel Nederland BV, TSTH – Tata Steel Thailand, LTI – Lost Time Injuries LTIFR - Lost Time Injury Frequency Rate, TCOC – Tata Code of Conduct, tcs – per tonne of crude steel, SPCs – Steel processing centres.

- For Non-Managerial staff for Indian operations only

- Employees on Roll - No. of permanent employees of Company (officers + non-officers) except those on deputation + doctors on contract

- Waste from last year was utillised this year hence, it is marked above 100%

- Only crude steel making sites

Strategic Objectives

Our building blocks

Strategy Road Map 2030

At Tata Steel, we aspire to be future-ready structurally, financially and culturally, in our pursuit to be the most valuable and respected steel company in the world. Following are the strategic objectives that Tata Steel aims to achieve across geographies

Strategic Enablers

- SE1

Best place to work for in manufacturing in India

- SE2

Top 5 in technology in steel industry globally

- SE3

Digital leader in steel industry globally

- SE4

Foster a culture which makes Tata Steel future-ready

Our ESG Goals

Driving responsible actions

Our ESG goals serve as the foundation of our sustainability journey as we aim to reduce our carbon footprint, accelerate the adoption of renewable energy, prioritise workplace safety, foster an inclusive culture, and uphold ethical business practices.

Environment

-

Long-term Goal

Net Zero emissions for the Tata Steel Group by 2045.

Climate Change

Climate Change

-

Short-term Goal

Achieve material efficiency of 99% at all Indian steel making sites by 2025

-

Long-term Goal

- Sustain material efficiency at 100% at all Indian steel making sites by 2030

- Increase Tata Steel’s Industrial By-product Management Division’s EBITDA by 2.4 times over FY2019-20 by 2030

- Build a 5 MnTPA recycling business in steel and other business in India by 2030

Circular Economy

Circular Economy

-

Short-term Goal

Achieve specific dust emission intensity of 0.43kg per tonne of crude steel in India by 2025

-

Long-term Goal

Achieve benchmark status specific dust emission intensity in India by 2030

Dust Emission

Dust Emission

-

Short-term Goal

Cover 100% sites under Biodiversity Management Plans across India, UK and Netherlands by 2025

-

Long-term Goal

Strive for no net loss of biodiversity in designated areas of influence in India by 2030

Biodiversity

Biodiversity

-

Short-term Goal

Cover 100% of steel making and downstream sites under Life Cycle Assessment in India by 2025

-

Long-term Goal

Disclose environment performance of 100% of products in India by 2030

Product Sustainability

Product Sustainability

-

Short-term Goal

Achieve specific freshwater consumption of 2.0m3/tcs across all steel making sites in India by 2025

-

Long-term Goal

Achieve specific freshwater consumption of <1.5 m3 per tonne of crude steel across all sites in India by 2030

Water

Water

Social

-

Short-term goal

Achieve 25% diversity in workforce for Tata Steel Limited by 2025

-

Long-term Goal

- Increase diversity in job with persons from non-western background to 14% for Tata Steel Nederland by 2027

- Women in vocational technical positions to grow to 5% for Tata Steel Nederland by 2027

- Women in decision-making positions to increase to at least 30% for Tata Steel Nederland by 2027

- Tata Steel UK to aim to have 25% women employed across the business

Workforce Diversity

and Inclusion

Workforce Diversity

and Inclusion

-

Long-term goal

Achieve zero harm for Tata Steel Limited by 2030

Safety

Safety

-

Long-term goal

Reach >10 million lives per annum through Corporate Social Responsibility initiatives by 2030

Local Community

Development

Local Community

Development

Governance

-

Short-term goal

Coverage of 100% critical supply chain partners for Environment, Social and Governance risk assessment for Tata Steel Limited by 2027

-

Long-term goal

Integrate Environment, Social and Governance performance of critical supply chain partners in procurement decision-making for Tata Steel Limited (Assessment & coverage in line with Responsible Steel guidance) by 2030

Supply Chain

Supply Chain

-

Short-term goal

Achieve ‘Certified Site’ certification for all existing steel making sites in India by 2025

-

Long-term goal

Achieve ‘Certified steel’ certification for all sites in India by 2030

ResponsibleSteel

Certification

ResponsibleSteel

Certification

-

Long-term goal

Be amongst top 5 in technology in steel industry globally by 2030

R&D and

Technology

R&D and

Technology

Opportunities

Growth catalysts for future

With increasing infrastructure development, growing urbanisation and a drive towards sustainable solutions, the steel industry is poised to unlock significant opportunities, creating a favourable outlook for the sector.

Read MoreRisk Management

Safeguarding our future growth

At Tata Steel, we have deployed a structured and uniform Enterprise Risk Management framework to proactively identify, assess, monitor and mitigate risks across the Company. This framework is essential in driving business resilience in a VUCA (Volatile, Uncertain, Complex, Ambiguous) world.

Read MoreStakeholder Engagement

Aligning aspirations with business goals

Our stakeholders define us, shape our journey, and guide our purpose. Their insights navigate challenges, uncover opportunities, and build an inclusive, sustainable future.

Materiality

Prioritising issues key to value creation

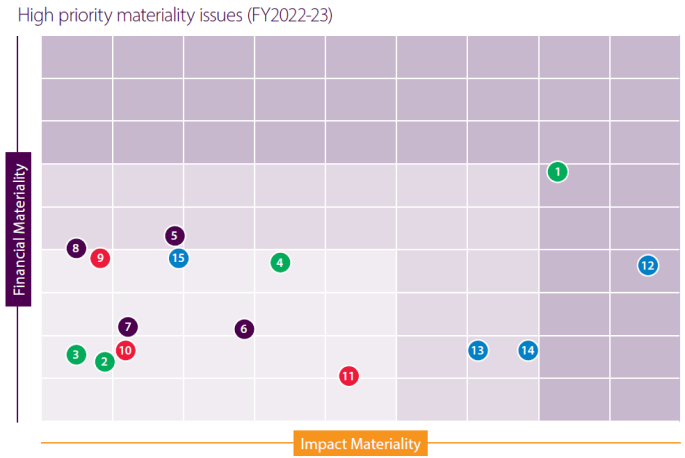

At Tata Steel, we make concerted efforts to prioritise the concerns of our key stakeholders. We use the Materiality Assessment approach to engage with all our stakeholder groups, in order to understand their key issues and focus areas.

Based on the independent analysis, the following high priority Material Issues have been identified from the set of material topic listed for Tata Steel on a consolidated basis:

Environmental

Operational

- Occupational Health and Safety

- Air Pollution/Air Quality Management

- Biodiversity

- Research and Development/ Technology, Product and Process Innovation

Social

- Supply Chain Sustainability

- Employee Well-being and Development

- Community Support and Corporate Social Responsibility (CSR)/ Building Thriving Communities

Governance

- Corporate Governance

- Business Ethics, Integrity and Transparency

- Stakeholder Engagement

- Risk Management

Our Capitals

Awards

Recognised for

success

World Economic Forum

Jamshedpur Steel Plant recognised as the Advanced 4th Industrial Revolution Lighthouse.

worldsteel

Recognised by worldsteel as 2023 Steel Sustainability Champion for the 6th consecutive year; among the only two steel companies in the world to receive this recognition every year since the programme’s launch in 2018

ResponsibleSteelTM

Jamshedpur Plant is India’s first site to receive ResponsibleSteel certification.

CDP

Recognised as 2022 ‘Supplier Engagement Leader’ for its efforts in measuring and reducing environmental risks across its supply chain.

Indian Bureau of Mines (IBM)

Noamundi and Joda East Iron Mines have been accorded a 5-Star rating for sustainable development for the year 2021-22.

Randstad Employer Brand Research (REBR)

Recognised among India’s top 10 most attractive employer brands in India 2022