Intellectual Capital

Our intellectual capital encompasses our wealth of

knowledge, expertise, patents and technological

advancements, driving innovation, operational

efficiency and creating the organisation fit for the

future in a

sustainable way.

SDGs impacted

`0 crore

R&D spend

0

New products developed

Material issues addressed

- Greenhouse Gas Emissions and Climate Change Management

- Air Pollution/Air Quality Management

- Energy Efficiency/Energy Management

- Circular Economy/Recycling of By-products

- Research and Development/ Technology, Product, and Process Innovation

- Risk Management

- Sustainability

Strategic linkages

SO1

SO2

SO3

SO4

SE

A culture of fuelling innovation

At Tata Steel, we aspire to be among the top 5 global technology leaders in the steel industry. We have consistently used technology and innovation to build a rich portfolio of future-ready products. New products developed by the Company are aimed towards attaining and retaining leadership in the chosen segments such as automotive, construction and oil & gas. Technology-led environment leadership is focused towards low-carbon transition, reducing dependence on freshwater consumption, maximising value from waste, establishing circular economy and developing technoeconomic solutions to use low-grade raw materials.

Developing disruptive sustainable products and processes is our primary R&D focus, and we developed cutting-edge steel products during the year including cryogenically treated bearings for automotive segments, and API X65 sour grade steel for Hydrogen transport. During the year, ‘Column Flotation’ - an advanced flotation technology, was implemented, which helped improve fine coal yield by 5%. Additionally, several technology development programmes focused on decarbonisation have been launched across different technology-readiness levels.

Tata Steel also continued trials at

its HIsarna pilot plant in IJmuiden. The

HIsrana technology is more efficient

than the current process because it no

longer requires

pre-processing of the

ores and metallurgical coal. HIsarna,

along with the Carbon Capture Storage

and Utilisation technology can lead to

significant reduction in emissions. Tata

Steel intends to build a second larger

demo plant in India.

In line with the strategic goal

to generate ‘value from waste’, in

FY2022-23, we commercialised a first-of-its-kind process technology that uses steelmaking slag and

low-grade

ore to produce a high-value product

‘High Phosphorus Pig Iron’ (HPPI). The

technology has been developed over

the last 10 years and has been granted

three patents. HPPI finds use in pig iron

foundries and value-added products

such as in sacrificial anodes, aluminium

smelters, etc.

Continuing the work on monetisation of Intellectual Property developed in-house, we have set up a 25,000 tonnes per annum production facility in Jamshedpur for Dhurvi Gold – a soil conditioner made from steelmaking slag.

Innovations recognised

As a testimony to our

priorities and relentless

efforts in the field of

innovation, Tata Steel

featured among the top 50

innovative manufacturing

companies in India at the

CII Industrial Innovation

Awards 2022. It was also

recognised as Asia’s IP elite

2022 by IPBC, the world’s

pre-eminent IP business

event.

Enabling technology-led environment leadership

‘MaterialNEXT’, a flagship open innovation

programme organised by Tata Steel

Research and Development infrastructure

0

Patents filed

0

Patents granted

We leverage our in-house capabilities as well as external expertise through strategic collaborations, to accelerate the deployment of breakthrough technologies at scale. In FY2022-23, we established a Centre for Innovation in Mobility at Indian Institute of Technology, Madras Research Park, where work will be carried out on multi-material solutions for light-weighting, vehicle tear-down and advanced mobility solutions, such as hyperloop. We entered into Memorandum of Understanding with TuTr Hyperloop for development and deployment of Hyperloop technology and with Indian Institute of Technology (Indian School of Mines), Dhanbad to establish a Centre for innovation in Mining & Mineral Beneficiation. We onboarded multiple start-ups during the year and 34 fully-funded trials were conducted across the steel value chain. We entered into strategic collaborations with 8 start-ups. The 3rd edition of ‘MaterialNEXT’, Tata Steel’s flagship open innovation event, registered more than 150 active ideas from more than 45 academic/research institutes.

R&D building,

Tata Steel Jamshedpur

Key new product developments

In line with the vision of becoming the best-in-class manufacturer and preferred choice of steel mills, we developed high-value products across segments, including advanced highstrength steel for automotive grades for bulk trailer application. In the Lifting & Excavation and Engineering segment, we developed steel for telescopic boom arm application for JCB and steel with impact toughness guarantee at -48°C, for arctic region transformer covers. Tata Steel also secured approvals for Chromium-free secondary coating for fuel tanks for Bharat Stage VI compliant two-wheelers.

In order to maintain the leadership position in the rebar segment, Tata Steel developed high strength, high ductility 6 mm air cooled rebars, with superior weld shear strength for welded wire mesh application. For the first time in India, we developed rebar to cater to the requirement of high strength corrosion resistance.

Tata Steel in UK is involved in the World Auto Steel E-Mobility Project that aims to deliver a fully designed and analysed autonomous vehicle utilising the latest steel grades in development, aimed at a 2035 launch. The project has completed the design phase and will be publicly launched later this year.

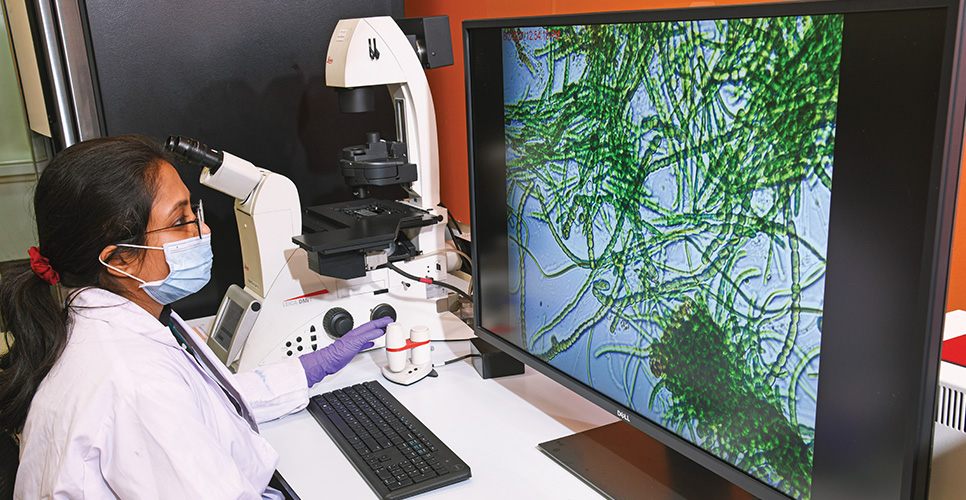

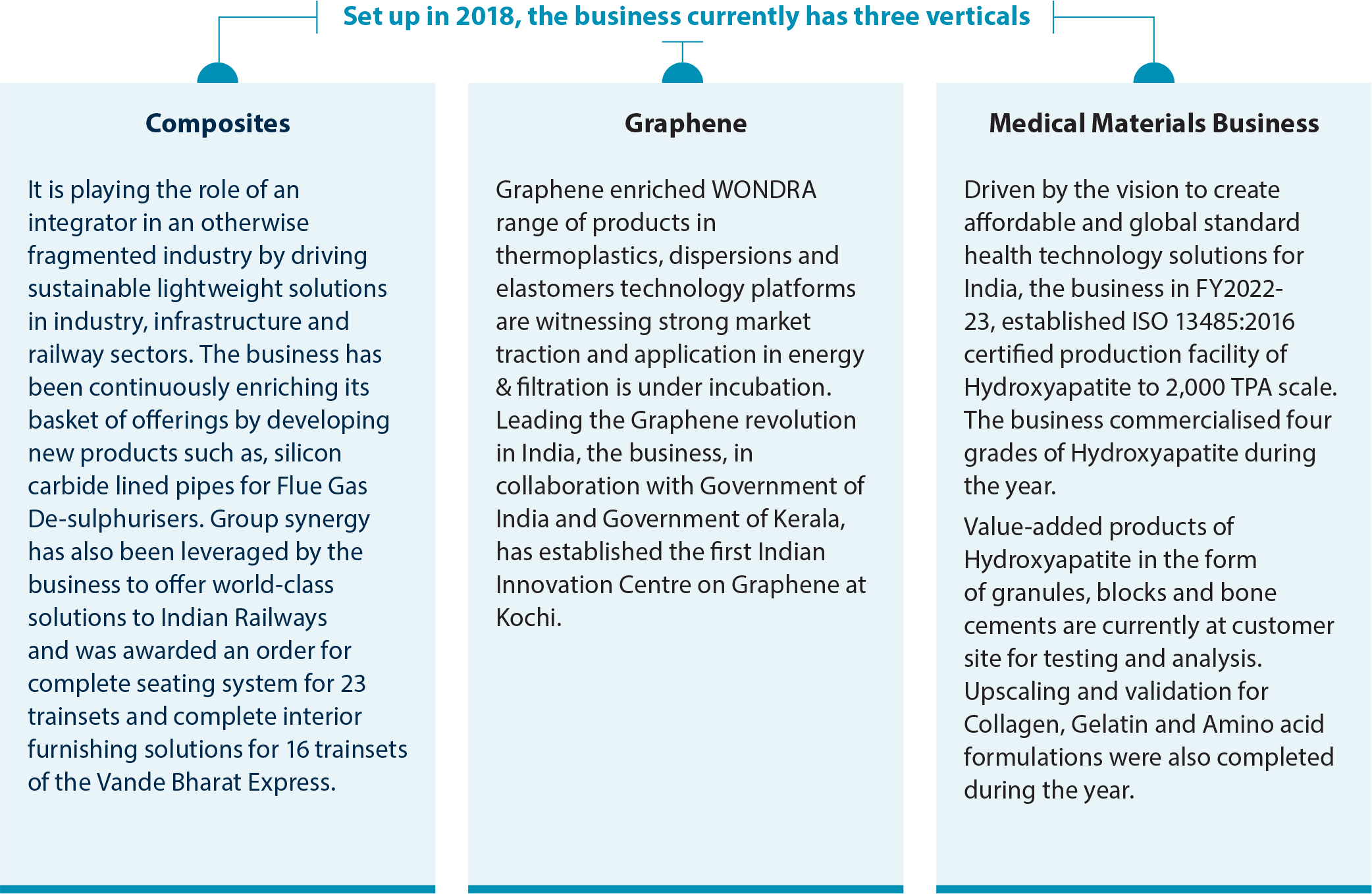

New Materials Business (NMB)

NMB was set up with the vision to create knowledge-intensive businesses by exploring

opportunities in materials beyond steel, to counter the cyclicality of the steel business.

FRP Composites based seating system and interior furnishing solutions for Vande Bharat Express

Way forward

Tata Steel is looking to accelerate innovation and technology leadership through strategic collaborations with various research and industrial organisations. We are also exploring partnerships with start-ups and grow adjacent revenue streams by commercialising in-house intellectual property through innovative products in new markets to achieve exponential growth in new materials, with world-class technologies and products.

TQM and Shikhar25

The Total Quality Management (TQM) way of working is embedded in the culture of Tata Steel. As we are growing in size, spreading to multiple locations and venturing into new business areas, we have placed renewed focus on uniform deployment of TQM and to keep the initiatives up to date. To make the operations efficient and reliable and its products and services competitive, we placed equal impetus on sustenance, improvement and innovation.

The Shikhar25 programme, a multi-dimensional and cross-functional initiative, is an EBITDA-focussed improvement programme to bring key structural changes across the value chain. Shikhar25’s governance structure is made up of cross-functional teams called ‘IMPACT Centres’ across the Tata Steel group. Currently, there are 50 IMPACT Centres deploying TQM techniques for improving operational efficiency, process improvements, product mix optimisation, waste reduction and recycling, energy efficiency and revenue maximisation. The process includes benchmarking of operating performance indicators and identifying enablers to achieve best-in-class yield, energy efficiency, throughput and quality. During the year under review, the Shikhar25 programme achieved performance improvements of ₹6,309 crore (including ₹4,299 crore of value protection initiative).

With increase in complexity due to multilocational functionality, it was also important to be agile enough to learn, evolve and transform faster and to keep pace with the changing business needs. The impetus was on driving value by enabling global optima and resource synergy for the Tata Steel group, resulting in an estimated synergy benefit of c. ₹446 crore.

The well-entrenched Shikhar25 programme is leveraged extensively to drive digital initiatives across the value chain. During the year under review, the Company, through its Shikhar25 programme, achieved performance improvements of nearly ₹1,202 crore via Industry 4.0.

Tata Steel runs similar programmes in the Netherlands and UK and the estimated benefits in FY2022-23 were €112 million and £52 million respectively.

Tata Steel’s participation and recognition in the Tata Group level Tata InnoVista competition over the last few years has been exemplary. In FY2022-23, we registered our best performance by bagging 6 out of 15 awards. To take its innovation journey to the next level, "Tata Steel InnoVista", an in-house platform, was launched to showcase innovations within the Company’s own Value Chain. Tata Steel was also awarded under the categories of Business Innovation and Potential Innovation, in the International Quality Innovation Award organised by China Association of Quality.

Tata Steel received the coveted ‘JRDQV Award’ and was recognised as ‘Benchmark Leader’ under the flagship Tata Business Excellence Model Assessment of the Tata Group.

Power Supervisory Control and Data Acquisition (SCADA), Tata Steel Kalinganagar

Tata Steel receives the coveted JRDQV award

Industry 4.0 - Knowhow and Capabilities

Integrated Remote Operations Centre, Tata Steel Jamshedpur

In our three phased digital transformation journey (Cloud, Data, Artificial Intelligence), significant investments made in the first two phases are paying rich dividends. Enabling location-agnostic work has helped us create a safer workplace and better working conditions for employees, fostering collaboration and driving synergy. Tata Steel’s Narrow Artificial Intelligence capabilities continue to support its connected operations and business platforms through improvements in yield, energy, throughput and quality. Intangible benefits are being delivered through a personalised talent marketplace for the Company’s employees and a hyperpersonalised experience for its online customers, enhancing customer and employee engagement. Video analytics solutions are helping us capture potential safety hazards to enable proactive interventions and help deliver our committed goal of Zero Harm. These are being powered by 250+ Artificial Intelligence/Machine Learning models deriving insights from over 3 Petabytes of data.

During the last year, we filed for nine patents (taking the total to 129) and were granted four patents (taking the total to 72) in the areas of digital, analytics, sensorisation and plant automation.

We are one of the first enterprise users of the latest Large Language Models (like ChatGPT) in a private and secure cloud, to unlock insights from internal data sources. We are also actively experimenting and future-proofing our business through investments in key emerging technologies such as the Metaverse and Private 5G networks, to build a truly connected enterprise. It is our core belief that the benefits derived from these technologies will be essential to compete and grow in the marketplace of the future.

Protecting privacy and data security

Protecting personal and financial information, using it only for the mentioned purpose and handling it responsibly, are of utmost importance to Tata Steel. We have built internal controls, policies and security measures, designed to keep this information safe and we require that third parties, such as our suppliers and vendors, preserve our high standards and protect data. Customers need to know what we are doing with their personal information and we strive to provide them with clear, user-friendly explanations of our privacy practices, including how we collect, share, use and protect their information and what choices they can make to limit the sharing of personal information. We also let customers and other stakeholders know in case of any material changes to our privacy policy. We safeguard personal information through a wide range of technological, administrative, organisational, and physical security measures. In addition, our Code of Conduct and related policies for ethical business conduct include specific guidelines about how employees should safeguard confidential information. We have a formal privacy incident management process in place to respond to any suspected or actual incident involving unauthorised access to personal information, its availability or an impact to its integrity. We notify impacted individuals of privacy breach incidents in accordance with the applicable laws. We are always investing in enhanced data privacy and security solutions to safeguard information.