Report Menu

Report Menu

Supply Chain

Aiming for delivery compliance

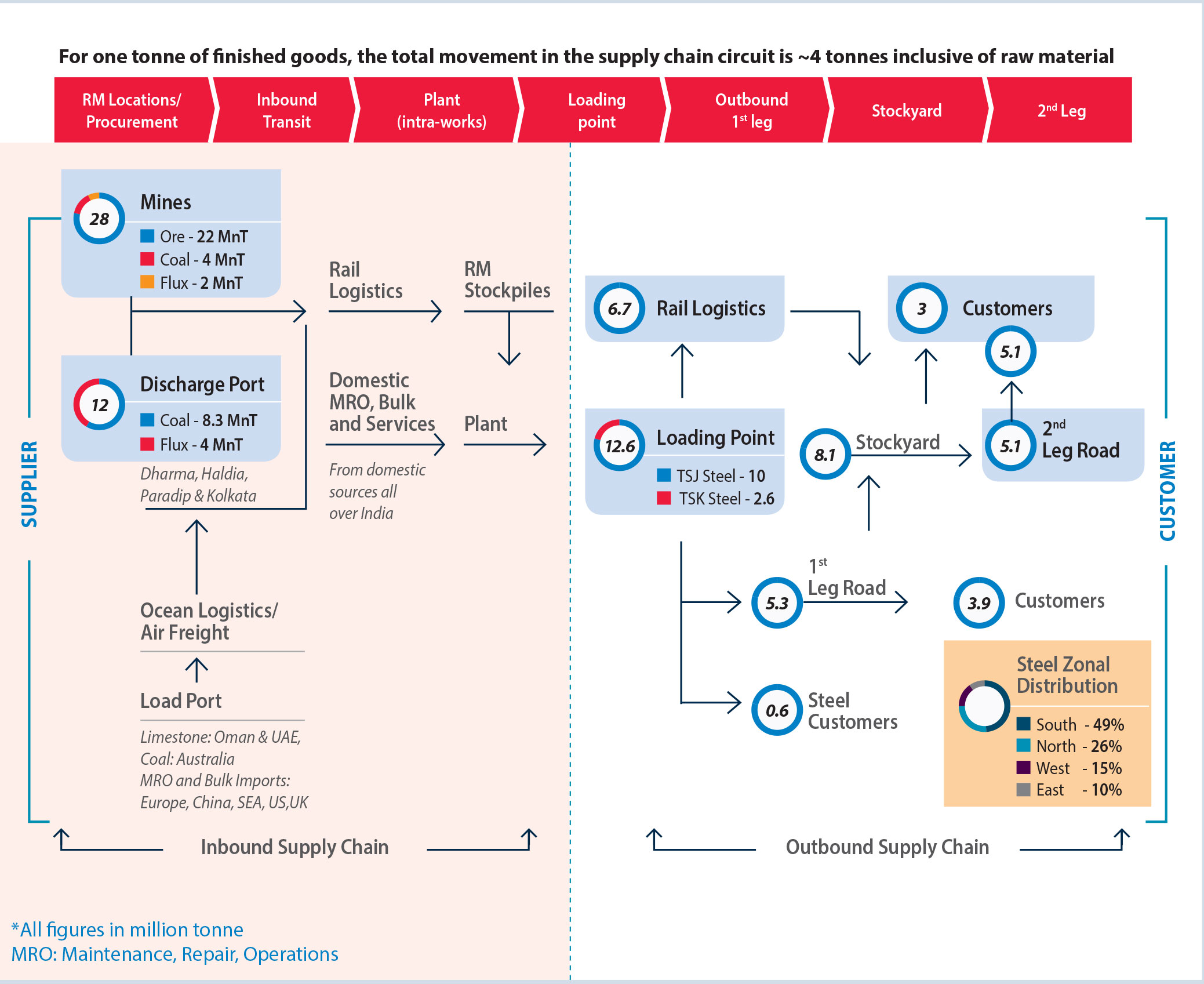

Supply chain is a critical element in Tata Steel’s value-creation process for ensuring on-time delivery of the right quality of raw materials, other goods and services to manufacturing locations, and finished products to the customers. Storage of semi-finished and finished products is a critical process with respect to timeliness of delivery, security and preserving quality.

Supply Chain

KEY

AREAS

SO2

- Optimising inbound & outbound logistics network

- Managing suppliers & channel partners

Our major manufacturing locations are located in the eastern part of the country, in the states of Jharkhand and Odisha, while Profit Centres such as Wires Division, etc. and customer delivery points are located pan-India. To meet the delivery and quality requirements of customers, we have steelprocessing centres and stockyards at strategic locations across the country to optimise the delivery time and cost. Our captive iron ore mines and collieries are located at sites around Jamshedpur and Kalinganagar.

- While railways are the most preferred mode of transportation in India from an environment point of view, it is wholly owned by the Government, which allocates the wagons to various agencies in the country. For the raw material segment, we are totally dependent on the Indian Railways for inbound transportation. We have closed-circuit rakes running between the captive mines, ports and manufacturing locations. We are one of the first in the steel industry to capitalise on incentives by the Indian Railways – Special Freight Train Operator (SFTO) Scheme and long-term tariff contract.

- The road conditions are not ideal for transportation of high-end steel products, which have to travel as far as 1,700 kms from the manufacturing locations to pan-India. Inland waterways in the country are in the early stages of development. Hence, it is not an open option at this stage, even though it is the most environment friendly mode.

- Tata Steel plays a pivotal role in ensuring close co-ordination and planning between overseas miners, load ports, ship owners, port authorities in India, the Indian Railways and our plants receiving the raw materials. We are one of the first major steel manufacturers to initiate the deployment of energy-efficient and environment friendly vessels for ocean transportation.

Therefore, we need to adopt multiple modes of transportation, taking into consideration the above constraints, aiming for the best possible delivery compliance and cost while taking utmost care of safety and the environment.

In FY 2017-18, Tata Steel imported almost 8.3 Million Tonnes (MnT) of coal from Australia, New Zealand, and North America, Canada/US and CIS; 4 MnT of fluxes were imported from the Middle East and Vietnam.

With increasing focus on environment and on de-risking our supply chain from emerging regulatory and other climate change risks (Refer 30 and 31 on Risk Governance and Management), we are now enhancing our focus on a Green Supply Chain and exploring the concepts of third-party logistics, modern state-of-the-art warehouses, use of energy-efficient and newer design eco-friendly ships, coastal shipping to reduce landside tonne miles and use of digital meals to simplify the cargo flow of raw materials and other bought-out goods (maintenance repair operations, bulk, etc.) and services. We ensure the implementation of Human Rights throughout the supply chain. The schematic depiction of our supply chain with the flow of materials is shown below:

Central warehouse at Jamshedpur

Key Enablers and Initiatives

| project description | impact |

|---|---|

|

1

Reduction of carbon emissions

by hiring at least 50% vessels

with GHG emissions rating of

class A to D |

Almost 65% vessels hired of GHG class A to D. Average grams of CO2 emissions per tonne nautical mile for vessels hired by Tata Steel in FY 2017-18 was 4 gm as compared to the global average of 10.9. ** |

|

2

Reduction in the consumption

of wooden dunnage used in FG

steel dispatch by introducing

SFTO rakes with inbuilt saddles |

|

|

3

Develop and increase business

with underprivileged and DP

(Displaced) Vendors |

Development of the few first-generation entrepreneurs from the underprivileged section of the society with a business volume of ~`80 Cr. |

|

4

Implementation of the Solid

State Interlocking (SSI) system

to improve safety in rail

network |

|

|

5

Implementation of Engine

on Load (EOL) concept in raw

material circuit for the first

time in the steel industry |

|

* Selected projects. Not comprehensive.

** Source: BIMCO (Baltic International Maritime Council) and Rightship – a Maritime Risk Management and Environmental Assessment Organisation.

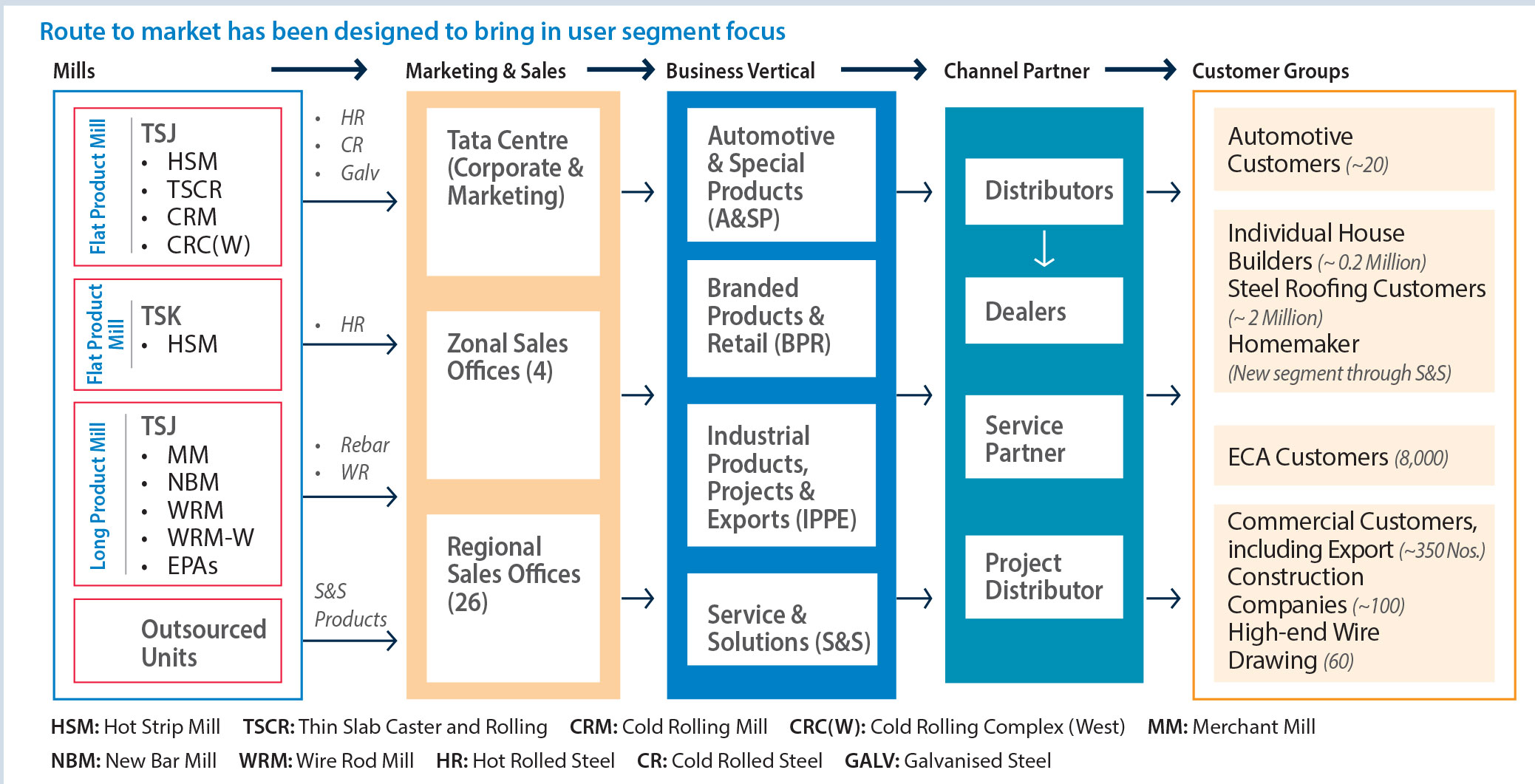

Pan-India retailer reach and a network of service partners in key consumption centres provide a unique competitive advantage to the TSL market

| Plant Warehouses | Jamshedpur and Kalinganagar |

| Hubs | 6(Delhi, Faridabad, Kolkata, Nagpur, Vijayawada, Chennai) |

| Stockyards | 18 (pan-India) |

Key Facts

- 100% fleet covered by vehicle tracking system

- Judicious mix of rail (~60%) and road (~40%) movement (cost effective and timeliness)

- 150 sales officers in 26 locations (customer account managers for relationship building and ensuring service)

- 193 distributors, 1,500 distributors’ feet, 11,883 dealers (strong network across India) reaching out to ~650 districts (95% coverage)

- Theory of Constraints (TOC) supply chain implemented in all product categories for retail sales (central warehouse enabled)

- Local/ customised production enabled by 24 Steel Processing Centres (SPCs) across Steel and Profit Centres

- Company distributor owned service centres for last point processing

Raw Material handled (MnT)

Supply Chain

Way Forward

- Network optimisation for improving the reliability and cost performance of the supply chain

- Asset-light and agile growth through utilisation of Private Freight Terminals (PFTs)

- Coastal steel shipping as a de-risking mechanism, for reduction in transport-related CO2 emission and ensuring sustainable supplies for our customers in South and West India

- Connecting North-East India through barge transport on inland waterways from Kolkata/Haldia through Bangladesh – this route would avoid long-winding and expensive truck routes to North-East India

- Economic speed management of vessels whenever and wherever possible – close co-ordination by all entities in the supply chain

Our Performance

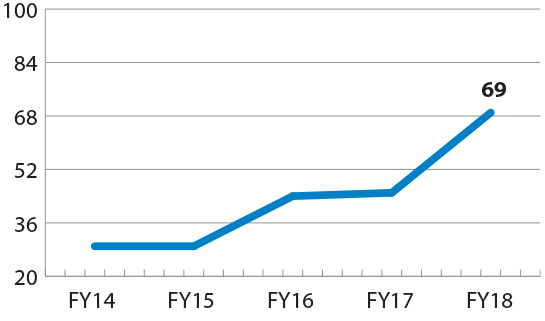

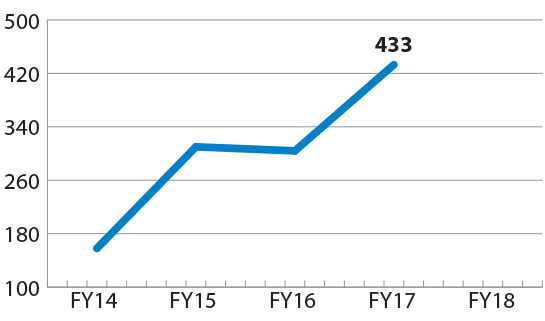

Number of underprivileged suppliers (Suppliers from the Scheduled Castes and Scheduled Tribes Community) |

(No.) |

Suppliers trained through Vendor Capability Advancement Programme (VCAP) |

(No.) |

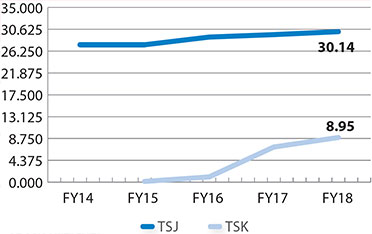

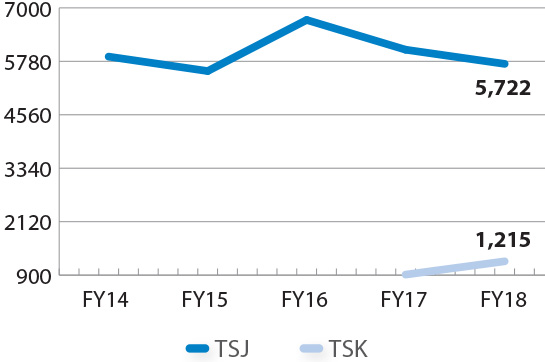

Outbound despatch volumes: Rail (TSJ and TSK) |

(kT) |

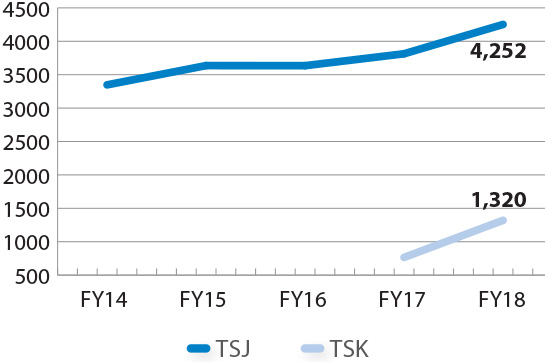

Outbound despatch volumes: Road (TSJ and TSK) |

(kT) |