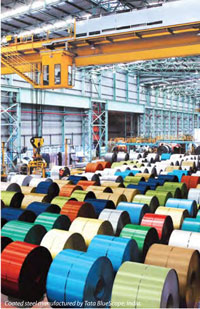

Coated steel manufactured by

Tata BlueScope, India. |

|

Tata Steel has plans for a comprehensive growth strategy with initiatives in downstream linkages and investments in supply chain logistics.

|

| Tata BlueScope Steel |

Tata BlueScope Steel (TBSL) is an equal joint venture between Tata Steel and BlueScope Steel in the field of coated steel, steel building solutions and related building products. The Company operates in the SAARC region.

Tata BlueScope Steel has three business divisions - Coated Steel, Building Solutions and Building Products.

The Coated Steel business markets metallic coated and pre-painted steel for the construction industry. It offers premium brands such as ZINCALUME® steel and COLORBOND® steel. The Coated Steel facility at Jamshedpur has an annual metallic coating capacity of 250,000 tonnes, including pre-painting capacity of 150,000 tonnes.

The Building Solutions business manufactures and supplies pre-engineered building solutions. Its premium brands include BUTLERT BUILDING SYSTEMS and ECOBUILDT BUILDING SYSTEMS. The Building Products business manufactures and supplies roll-formed roof and wall cladding solutions and related building components. It offers premium brands like LYSAGHT® range of roof and wall cladding solutions, DURASHINE® range of products and EZYBUILD® solutions. The Company's building solutions and building products businesses have state-of-the- art manufacturing facilities at Pune, Sriperumbudur and Bhiwadi supported by a wide network of regional and sales offices located across India.

Tata BlueScope Steel is playing the crucial role of completing the value chain in the form of efficient downstream steel products that meet market expectations for sustainable construction solutions. With TBSL, Tata Steel is better poised to increase per capita steel consumption in Construction sector. |

| Continuous Annealing and Processing Line |

The implementation of the 0.6 mtpa Continuous Annealing and Processing Line (CAPL) project at Jamshedpur for the production of automotive cold rolled flat products is progressing as per schedule for its commissioning by the end of 2013. A Joint Venture Company between Nippon Steel Corporation and Tata Steel India will complete the project implementation and serve the growing needs of Indian automotive customers for high-end cold rolled coils and sheets.

CAPL technology is best suited for the production of high-quality automotive skin panel steels and for the production of high-strength grades of cold rolled steels. These product offerings will expand the existing product range of cold rolled coils and sheets for automotive customers, thereby enabling them to substitute imports and achieve their objective of localisation.

|

| |

| Dhamra Port Company |

The Dhamra Port Company Limited (DPCL) is a 50:50 joint venture between L&T and Tata Steel. DPCL has been awarded a concession by the Government of Odisha to build and operate a port north of the mouth of the river Dhamra in Bhadrak district, Odisha on a BOOST (Build, Own, Operate, Share and Transfer) basis for a period of 34 years, with an option for renewal.

Situated between Haldia and Paradeep, the port at Dhamra will be one of the deepest ports of India with a depth of 18 metres, which can accommodate super capesize vessels up to 180,000 DWT. The master plan provides for 13 berths and, at its full capacity, the port is expected to be capable of handling more than 100 mtpa of dry bulk, liquid bulk, break bulk, containerised and general cargo.

Dharma Port, India

The immediate hinterland of Dhamra is rich in mineral resources with reserves of iron ore, thermal coal, nickel, bauxite and chromite, all of which have brisk export demand. The area is also home to some of the largest steel producers in India who import coking coal to meet their requirements.

Presently two berths of the port have been fully developed. These are a mechanised import berth handling coal and limestone and an export berth for iron ore. The import

and export circuit is equipped with ship unloader, stacker reclaimer, RCC silos and rail-loading facilities. The estimated aggregate capacity of the import and export circuit is 27 mtpa. The project has already had a positive effect on the Company's logistics cost of imported coking coal.

|

| |

| Tata NYK |

Tata NYK Shipping Pvt. Ltd. is a 50:50 JV between Tata Steel Limited and NYK Lines, a Japanese shipping major. The Joint Venture was incorporated to meet the growing sea-borne trade requirements of the Indian market, including the Tata Group in anticipation of its expansion plans, which would increase dependence on sea-borne cargo. The Company is primarily in the business of owning, operating and chartering ships for carrying dry bulk and break bulk cargo including coal, iron ore, limestone and steel products with the capability of handling cargo originating in any geography.

The Company today has a diversified fleet of 14 vessels ranging from supramax, panamax and capesize vessels. It also has significant expansion plans in the near future. The cargo handled increased from 7.9 million tonnes in Financial Year 2010-11 to 11.2 million tonnes in Financial Year 2011-12. |

|