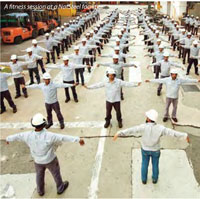

A fitness session at a Nat Steel facility. |

|

Across all its operational facilities, the Company implements policies that cover occupational and overall health..

|

| Policy |

Tata Steel embarked on its formal safety excellence journey in 2004 and since then, has made significant progress in its drive towards becoming a leader in industrial safety. The Group's Lost Time Injury Frequency Rate for Financial Year 2011-12 was 0.68, an improvement of 14% over last year.

'Health and Safety' is reviewed at all Board meetings of the Company with a Health, Safety and Environment committee established to carry out more detailed reviews. The integrated and systemic Health and Safety Management System, introduced in TSE in 2008 with a governance process for improvement actions and regular safety tours by the Board and executive members, has been developed for Group-wide application in the current year.

Specifically in India, a series of safety initiatives helped achieve an LTIFR (Lost Time Injury Frequency Rate) of 0.51. Some of these initiatives are given below:

Employees must wear safety equipment as stated in the Company's rules.

- Special drive focusing on Fatality Risk Control Programme (FRCP) and Elimination of Commonly Accepted Unsafe Practices (ECAUP), through which more than 10,000 unsafe conditions and 969 unsafe practices have been corrected.

- The Stock Yard Safety Management System was rolled out at all the 40 stock yards. A 15-point safety rule book on stock yard management was launched, followed by training for all workers and supervisors.

- The Safety Excellence Journey has set out standards and procedures and resulted in many improvements to processes, visual management and communications - all helping to raise awareness and foster a culture of safety. A 100-day Safety Excellence Journey campaign included safety training for senior leaders, and a 'train the trainer' programme for 24 plant managers.

- The Safety Excellence Journey has also been extended at Group companies in India namely JUSCO, ISWP, Dhamra Port Company Limited, TS Alloys, Tata Sponge Limited and TRL Krosaki Refractories Ltd. Tata Steel has also established a safety organisation for the greenfield project at Odisha.

|

| Process safety |

A comprehensive safety review process was conducted at Jamshedpur for the start-up of the new hot strip mill, blast furnace and a number of other key installations, helping to assess risks on new or modified facilities before the handover from project to operations team.

Nine high-hazard installations were modelled for toxic releases and explosions using specially-created 'Phast Risk' software. Tata Steel is the first steel company in India to use this advanced software, which is also in use at the Company's European facilities.

Process safety has been a constant focus for all high hazard facilities (HHF) in Tata Steel since 2008, when dedicated teams were put in place. They have identified high hazard facilities across the European operations, and are now carrying out process hazard reviews. Work is going on to determine the required safety integrity level with respect to identified safety critical systems.

To aid the management of change, a tool has been created for managing changes to plant, process and people, and a training package has been developed. Loss of containment reporting - recording and reporting any spill of (listed) hazardous substances above a threshold amount - has been extended to all Seveso II (COMAH and BRZO) sites and, from mid-2010, sites were required to report all spills of hazardous substances, including molten metal, and rank each event in terms of potential impact. These reports are being used to measure and improve process safety performance in the same way that the lost time injury frequency rate is used to monitor occupational performance.

|

| Occupational health |

Apart from the safety of its employees, Tata Steel also focuses on improving their health through its Wellness@Workplace programme.

As part of the campaign to reduce health exposures across Tata Steel in Europe, IJmuiden has been investing in structural measures to reduce and prevent exposure to emissions of diesel engines in enclosed areas. Dieseldriven equipment have been replaced where possible, and exhaust gases extracted. Some vehicles have been equipped with filters.

A comprehensive workplace health programme is in place in NatSteel. The percentage of staff with high total cholesterol decreased to 23.8% in 2010-11, from 34.4% the year before. Over the same period, the percentage of staff exercising regularly (three times a week, 30 minutes per session) increased to 39.5% from 36.4%.

The Vitality Centre, a lifestyle clinic at IJmuiden, the Netherlands.

Tata Steel won the worldsteel 'Safety and Health The Vitality Centre, a lifestyle clinic at IJmuiden, the Netherlands. Women employees benefit from the Women Health Improvement Project at Tata Steel. Excellence Recognition Award' for the second consecutive year. The award recognises excellence in a company's commitment and innovation in the pursuit of an injury and illness-free healthy workplace.

Woman employees benefit from the Women

Health Improvement Project at Tata Steel.

|

|