About Us

- Chief Speak- History

- Global Presence

- Organizational Structure

- Collaborations

- IPR and Publications

History

More than a century ago, the visionary founder of Tata Steel, Sir Jamsetji Nusserwanji Tata, was much impressed when he saw in America, Europe and Japan the prosperity that was created by the application of science to industry. He therefore instilled in the fledgling Tata Steel the scientific approaches to test and characterise raw materials and products.

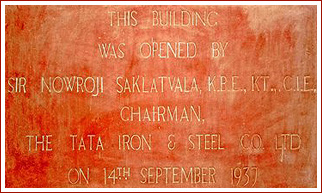

By 1937 his vision took grand shape by the establishment of this Research & Control building that today still houses these functions, presently called R&D, Scientific Services and Refractory Technology Group (RDSS Division).

This new Division in Tata Steel also meant the very start of Industrial R&D in all of India. It is a tell-tale sign of the vision and enlightenment of the House of Tata to set up such a ‘western’ concept in the then remote township of Sakchi.

During the years the Division has evolved and grown to meet the needs of the company. While initially the focus was on process monitoring and control, the 1940s saw a growing need for product development imposed on the company by the Second World War. Process innovation was earlier limited to making the best of local raw materials, but in the 1960s and 70s it started branching out into new process technologies to help compete with the fast growing public sector steel industry.

The economic liberalisation of the 1980s and 90s opened India to global competition. This spurred demand for more varieties of steel and R&D turned its attention to product development to meet the demands from sectors like automobiles, construction and engineered products.

Since 2000 the global growth in the steel industry has escalated the market prices of raw materials like ore and coal. This has forced R&D’s attention to process innovations to make use low cost raw materials and increase energy efficiency. Growing awareness on environmental issues and global warming is also driving R&D to look at reducing our environmental footprint.

The achievements and significance of this R&D have been lauded at national and international level. It was recognised with many awards, such as various awards for the ‘R&D efforts in Industry’ by the Department of Science and Technology (1990, 2001, 2007), the best R&D laboratory in India award by NACE International (2004) and the award for the highest number granted patents amongst Indian owned private companies by the Ministry of Commerce & Industry (2011).

The following are some important milestones in the history of the R&D and SS Division:

-

1937 : ‘Research and Control Laboratory’ opened on September 14 at its present location

-

1941-42 : R&D division played a key role in developing steel plates used to make armored vehicles (called Tatanagars) in the First World War; also developed corrosion resistance steel for the Howrah bridge in Kolkata, India

-

1955 : R&D division played a significant role in achieving the target of the Two Million Tonne Programme launched at Tata Steel, Jamshedpur

-

1980-81 : Phase I of Modernization – Relevant technologies were absorbed by R&D

-

1984-88 : Phase II of Modernization – R&D identified specific coal blends for coke making

-

1989-94 : Phase III of Modernization – R&D optimized process parameters for Slab caster, ‘G’ Blast Furnace, LD – 2 and HSM

-

1996 : RH-Degasser was commissioned and R&D played a significant role in optimization through simulation and modeling work

-

1997 : R&D received the ISO 9000:1994 certification

-

1998 : Development and release of IF-Nb and IF-Ti grades of steel for the auto industry for the first time in India

-

1999 : Established the characteristics of imported low volatile semi-soft coal for use in coke making and Blast Furnace injection

-

2000 : Development and introduction of dent-resistant grade steel for the auto industry for the first time in India. Phase IV of Modernization – Cold Rolling Mill was commissioned and R&D supported the optimization the pickling, cold rolling, annealing and galvanizing processes

-

2001-02 : QMS was upgraded and R&D received the ISO 9001:2000 certification. R&D introduced an offline simulator for predicting properties of Hot Rolled Coils

-

2002-03 : State-of-the-art water model laboratory was set up. Three new types of steel were developed

-

2003-04 : Quality Management System was computerized and strengthened. Five new products were developed

-

2004-05 : Two new hot rolled products were developed

-

2005-06 : Three new products were developed along with several processes resulting in the filing of several patents. Research efforts were directed towards several ambitious projects known as Thrust Area Projects

-

2006-07 : Considerable progress was made in the Thrust Area Projects. R&D added XRD, SEM and beneficiation facilities to its list of research facilities

-

2007-08 : R&D celebrated its 70th year by organizing four international conferences. Research was initiated in a new area of ‘energy efficient fluids’. A new wire product with thin organic coating on galvanized wire was developed and commercialized. New software to provide set-up guidance to operators of wire drawing lines was developed

-

2008-09 : R&D became part of the Global Research Development & Technology function of the Tata Steel group

-

2009-10 : QMS was further upgraded and R&D received the ISO 9001:2008 certification

-

2010-11 : R&D augmented it computational capability by commissioning ‘Reynolds’ - the fastest computer in the Tata Steel group. A state-of-the-art Bio-Remediation laboratory was set up

Home

Home Chief Speak

Chief Speak