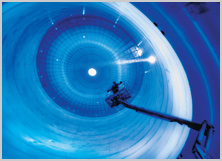

The HIsarna™ pilot plant at Ijmuiden,

the Netherlands

CLIMATE CHANGE STRATEGYClimate change is one of the most important issues facing the world today and the Group’s aim is to be a part of the solution. Five strategic priorities underpin this challenging objective. These are to:

- reduce emissions in the short to medium term, in line with current technology;

- invest in the research and development of longer-term breakthrough technologies;

- develop new products and services that reduce CO2 emissions through the life cycle;

- actively engage the workforce in this challenge; and

- lead by example within the global steel industry.

SHORT TO MEDIUM-TERM EMISSION REDUCTIONS A number of large-scale energy efficiency and emissions reduction projects have recently been commissioned, while numerous other schemes are in progress. For

example, the efficiency of the Group’s Indian operations is already being improved through the ambitious capacity expansion projects at the Jamshedpur Steel Works. The expansion will see Jamshedpur’s crude steel production capacity increase to 9.7 million tonnes by early 2012 – almost a doubling of output in a four-year period. Efficiency savings are being gained by replacing multiple small blast furnaces with a smaller number of high-capacity furnaces. Advances in technology have been and will continue to be exploited to achieve further carbon savings, through higher rates of coal injection, blast furnace top gas turbines for electricity generation, the recovery of waste heat to minimise

fuel usage and the establishment of thin slab casting and rolling to reduce the need for reheating. In Europe, in April 2010, the Group commissioned a £60 million energy efficiency scheme at its steelmaking facility in Port Talbot in the UK. This investment is reducing the site’s CO2 emissions through the re-use of gases generated at the BOS plant. The recovered BOS gas is being used to generate an extra 15MW of power –10% of the facility’s total electricity needs. Overall, the scheme will reduce CO2 emissions by approximately 250,000 tonnes per year.

BREAKTHROUGH TECHNOLOGY DEVELOPMENT The scope for achieving further significant CO2 emission reductions from the conventional iron and steelmaking process is limited by the laws of thermodynamics. Consequently, the production of hot metal, via the blast furnace route, must be placed on a completely new technological path if a step-change in emissions is to be achieved. For the long term the focus is on the collaborative ULCOS (Ultra Low CO2 Steelmaking) project aimed at reducing CO2 emissions from ore-based steelmaking by at least 50% per tonne produced by 2050. The ULCOS steering committee made a decision to build the HIsarn™ pilot plant at the Group’s site at IJmuiden, the Netherlands and construction was completed during the financial year. This technology aims at producing pig iron using raw materials in powder form, thus bypassing ore and coke agglomeration processes. The technology in principle offers a 20% energy (and CO2) reduction opportunity, and technically could be combined with carbon capture and storage to further reduce emissions.

Inside the gas holder - part of the BOS gas recovery scheme at Port Talbot, UK

VOLUNTARY AGREEMENTS The Group currently participates in a voluntary agreement with the Dutch government regarding energy efficiency improvements over the period 2009 to 2012. The primary requirement of the agreement is an energy efficiency improvement of 2% per annum, covering both energy used within the manufacturing process and energy saved across the product life cycle. The total energy efficiency improvement in 2010 was 2.8%. In the UK, the revised target within the Climate Change Levy (‘CCL’) agreement (i.e. a reduction in absolute energy consumption of 15.8% compared to 1997 levels by the end of 2010) was achieved. This ensures that the Group will continue to benefit from reduced rates in relation to the CCL for 2011 and 2012 (relief having been set by the UK government at 65% for all sectors that achieve their CCL agreement targets, reduced from 80% previously).

EU EMISSIONS TRADING SYSTEM (EU ETS) The EU ETS came into force on 1st January, 2005. The scheme currently focuses on CO2 emissions and applies to various production processes, including those used in the production of steel. CO2 emitting sites are allocated a certain number of emission rights and these sites have permission to emit CO2 up to the limit of their rights allocation. Any surplus in emission rights can be sold and any deficit can be purchased on the emission rights market. Phase 1 of the EU ETS covered the years 2005 to 2007 and Phase 2 covers 2008 to 2012, with usage of rights being externally verified and reconciled annually. Phase 3 will run from 2013 to 2020 inclusive. The Group met its environmental obligations in Phase 1 of the EU ETS and expects to do the same in Phase 2. |